When selecting a contactor for an electrical or industrial application, there are several key characteristics and factors to consider to ensure it meets the specific requirements of your system.

Here are the main aspects to look at:

- Rated Operational Voltage: Check the maximum voltage level the contactor can handle. This should match or exceed the voltage level of the circuit it will be used in.

- Current Rating: This is one of the most critical factors. The contactor should be able to handle the maximum current that the circuit will draw. This includes both the normal operating current and the inrush current (initial surge current) typical in motors and transformers.

- AC or DC Operation: Contactor coils can be designed for AC or DC operation. The choice depends on the control voltage available in your system.

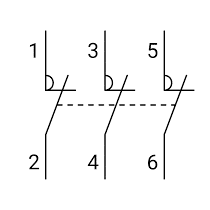

- Contact Configuration: Look at the number of contacts and their type – normally open (NO) or normally closed (NC). This should align with the control logic of your system.

- Size and Mounting Requirements: Consider the physical size of the contactor and how it will be mounted in your panel or system.

- Coil Voltage: The control voltage required to operate the contactor’s coil. This should be compatible with the control system used to operate the contactor.

- Environmental Conditions: Consider the operating environment. Factors such as temperature, humidity, and the presence of dust or corrosive materials can affect the contactor’s performance and lifespan.

- Duty Cycle: Ensure the contactor is rated for the type of load and operation frequency it will encounter. Different types are available for continuous, intermittent, or high-frequency operation.

- Auxiliary Contacts: Some contactors come with auxiliary contacts used for signaling and interlocking purposes. Check if your application requires these.

- Manufacturer and Brand Reputation: Choose a reliable brand known for quality and durability, especially for applications in critical systems.

- Certifications and Standards Compliance: Ensure the contactor meets relevant industry standards and certifications, which might be required for legal or safety compliance in your region or industry.

- Overload Protection Integration: Some contactors can be integrated with thermal or electronic overload relays for motor protection. Consider this if you’re using the contactor for motor control.

- Arc Suppression Features: In higher-power applications, the contactor’s ability to suppress and extinguish electric arcs generated during switching is important.

- Ease of Installation and Maintenance: Look for contactors that are easy to install and maintain, especially if frequent servicing is anticipated.

By carefully evaluating these factors, you can select a contactor that efficiently meets the specific needs of your application and ensures reliable performance.