Food Packaging AC Drives & HMI Units

Fuji Electric has provided the essential food packaging equipment needed for facilities in the Food & Beverage industry from assembly lines to packaging sectors. Our technology can simplify wiring for factories, measure the pressure when vacuum sealing finished goods, and minimize complex wiring. In addition, Fuji is trusted to improve efficiency, reliability, and sanitary for applications in this segment. Scroll down to view which AC Drives, HMI Units and Instrumentation & Control products are right for you.

AC Drives

Fuji Electric’s FRENIC-Mini Drive offers extended horsepower (up to 20HP) in a compact design. It is our most user-friendly drive yet, as the performance of the FRENIC-Mini has been improved and comes standard with RS-485, torque vector control, permanent magnet motor, and PID control. Our FRENIC-Mini Drive elevates the performance of a wide range of devices and equipment. Its capabilities give you the system integration, energy efficiency, reduced labor, and lower overall costs.

Features & Benefits:

Provides excellent performance for both single-phase and three-phase applications

Available in multiple configurations to support 1/8 HP up to 20 HP AC drives / variable frequency drives (VFD) / v/ Hz vector drives

Strikes an optimal balance between price and performance with expanded range of rated voltages

AC Drives for Food Packaging

HMI Units

Fuji Electric is one of the original manufacturers of human machine interfaces (HMI) from Japan since 1988, providing quality and reputable products worldwide. Our HMI’s can be used for all types of segments in the food and beverage industry from packaging to managing assembly lines. These devices can simplify wiring, minimize complex programming, and allow multiple data management and monitoring for single or multiple devices/factory. Our equipment can communicate multiple industrial communication protocol, while providing single point of monitoring and control. This functionality allows customers the ability to monitor and control multiple devices via HMI and can troubleshoot the machine while off location.

Features & Benefits:

- Operation Log Function – Allows viewing of the operation procedures that cause defects and production settings based on the date and time manufactured

- Recipe Function – Data can be read or written with ease; Recipe data can be stored in CSV files on a storage device connected to MONITOUCH

- PLC 8-Way communication – Programs for connection and control are not required and number of units can be reduced

- MES Function – Creating a separate program (Macro) on MONITOUCH allows notifications of replacement periods by tallying data in the database

- Device Memory Map – Reduce the work hours required to create transfer programs. Improved operation responsiveness

- Trend Graph – The screen overlaid with trend graphs can be updated allowing variations in production to be noticed using statistical process control (SPC)

- Ladder Transfer – Check and change ladders by connecting a PC to the V9 while leaving the cable between the PLC and V9 connected

- PDF Viewer – Paperless reduces paper costs and improves work efficiency since going back and forth between the cleanroom and office is not required

- VNC Function – This enables large machines and long lines, to be operated while also monitoring

- VPN Remote Access – Local situation can be analyzed and the time & expenses for dispatching employees can be reduced

HMI Displays for Food Packaging

Instrumentation & Control

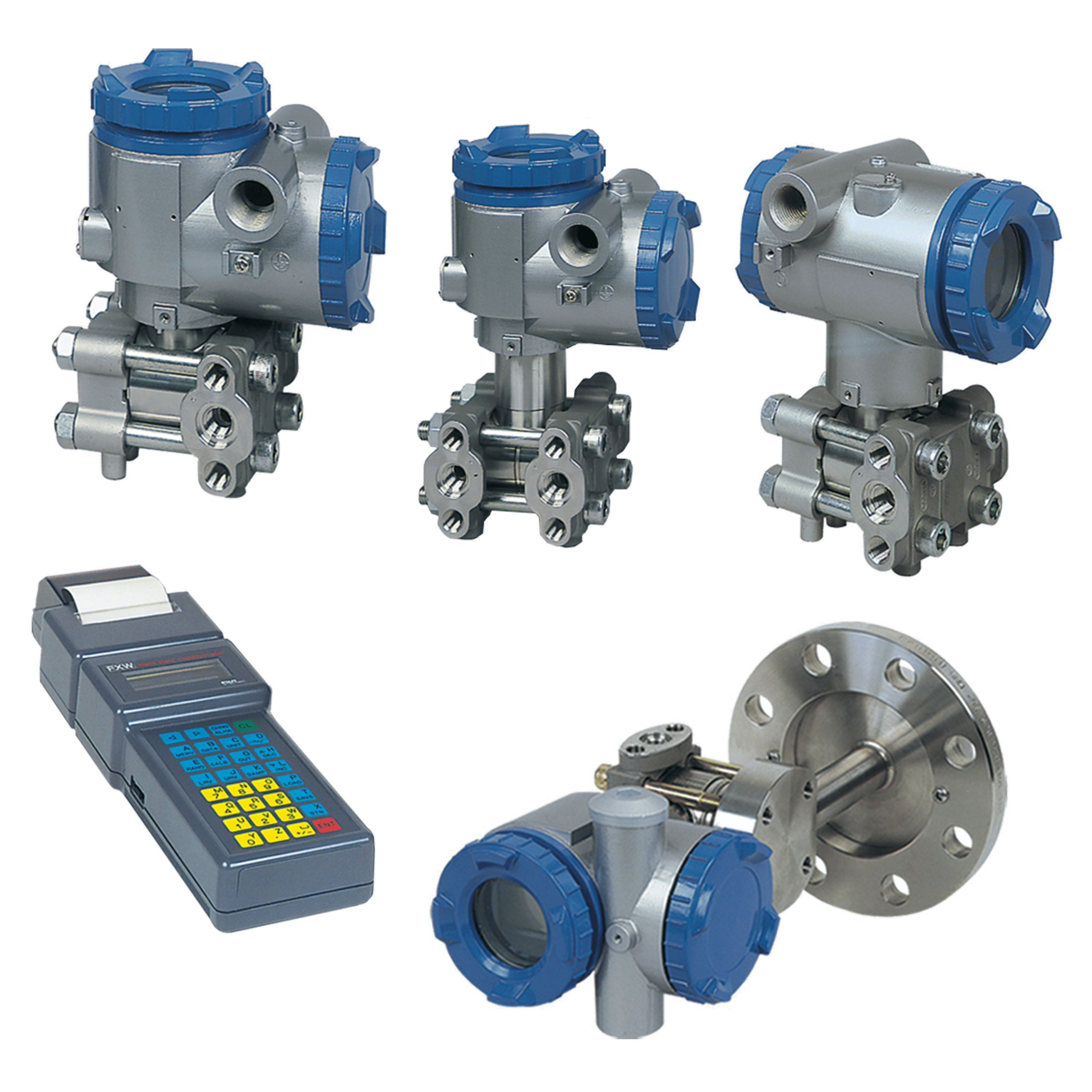

Fuji Electric provides the necessary food packaging equipment for facilities in the manufacturing and packaging sectors of the Food & Beverage industry. Our pressure transmitters are used to measure the pressure when vacuum sealing the finished goods in their packaging. Fuji Electric’s transmitters are built custom in-house for quick turnaround and delivery, and can apply a specialized industrial coating for protection against corrosion and sanitary purposes. Flow meters can be used to measure the flowrate in the filling, dosing and mixing by batch process when blending items together in the industry.

Benefits of Fuji Electric Instrumentation Products:

- Ultrasonic Flowmeters – Utilized for batch control and mixing applications, as well as for CIP and SIP cleaning processes

- Pressure Transmitters – High performance & reliability with a wide range of models for gauge or differential pressure, and flow with competitive low cost options

- Electromagnetic Flowmeters – Utilized for food and beverage applications to keep processes sanitary. Results measurements are independent of density, temperature and pressure

Instrumentation & Control for Food Packaging