Fuji Electric has developed high-performance IGBT (Insulated Gate Bipolar Transistor) modules to meet the need for smaller, efficient, and reliable high-power solutions in industrial, transport, and renewable applications. The High-Power Next Core (HPnC) modules set a new benchmark in power density, efficiency, and ease of use, allowing users to design compact, lightweight, and cost-effective power conversion systems.

This whitepaper explores key features and benefits of Fuji Electric’s HPnC 7th generation IGBT modules, highlighting improved packaging technology, electrical characteristics, and enhanced reliability. It also compares Fuji’s HPnC with typical high-power modules (HPMs), demonstrating how Fuji’s innovative approach offers performance advantages over competing solutions.

The Evolution of High-Power IGBT Modules

High-power IGBT modules, like the standard High Power Modules (HPM), have been a common solution for power conversion systems requiring high current or voltage ratings. These modules, housed in large packages, e.g., the 130mm x 140mm and 140mm x 190mm, have been widely used in industries like renewable energy, traction, and industrial drives. However, as the power electronics industry has advanced, the limitations of HPM have become apparent. The bulk and weight of these modules impact the overall system footprint and add complexity to the design process. Moreover, the overlap in the circuit layer of HPMs makes paralleling multiple modules challenging, typically requiring intricate bus bar designs and consideration of stray inductances.

Through extensive research and development efforts, Fuji has introduced several generations of high-power modules while improving power density, electrical performance, and reliability. 7th-gen HPnC modules are a major milestone in this journey. By utilizing advanced packaging and optimized chip technology, Fuji has reduced module size and weight while improving the electrical characteristics and simplifying the paralleling process.

7th-Gen IGBT Modules: A Closer Look at Fuji Electric’s HPnC

Fuji offers a broad range of HPnC module options to cater to diverse application requirements, with Silicon (Si) and Silicon Carbide (SiC) variants within the HPnC family. The Si-based HPnC modules are a cost-effective solution for applications that demand high efficiency, reliability, and power density. To meet the growing demand for even higher performance and efficiency, users can opt for SiC variants. SiC MOSFETs exhibit lower on-resistance and faster switching speeds than Si IGBTs, allowing users to design power conversion systems with ultra-low losses and high power density.

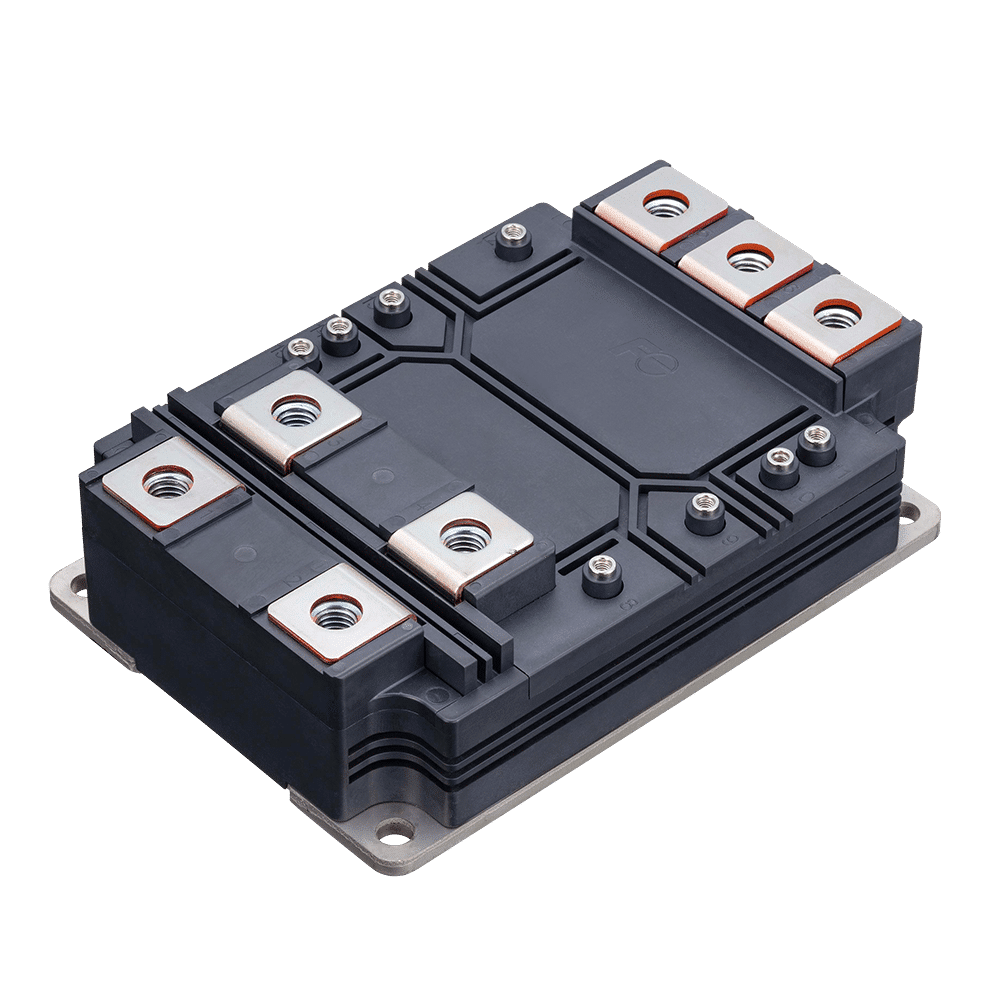

Compactness & Optimized Construction

One of the main benefits of Fuji’s HPnC modules is their reduced sizes and weight compared to standard HPMs. With a compact 99.5mm x 144mm package, this footprint reduction makes it easier to design space-efficient power conversion systems. Furthermore, they have a weight reduction of approximately 27% compared to HPMs. The lower weight can reduce overall system cost, as lighter modules require less robust mounting structures.

In addition to a compact and lightweight design, HPnC modules benefit from a simplified and optimized internal layout. A frequent challenge with using HPMs is paralleling modules and the need for complex bus bar designs due to the overlap of circuit layers. In contrast, Fuji HPnC modules adopt a straightforward approach by positioning the AC terminal layer opposite the collector and emitter circuit layer. This layout optimization simplifies the paralleling process and enables easy connection of modules without needing intricate bus bar designs. Moreover, the simplified layout reduces stray inductances, enables faster switching speeds, and improves overall performance.

Advanced Chip Technology

7th-Gen HPnC modules utilize Fuji’s latest X-Series chip technology, an advanced IGBT/FWD (free wheeling diode) chipset that offers several benefits over previous generations. Firstly, the X-Series IGBTs feature a lower collector-emitter saturation voltage (Vce(sat)) than their predecessors. This reduction in on-state voltage drop reduces conduction losses, resulting in higher efficiency and low heat generation. Moreover, X-Series IGBTs exhibit a lower surge voltage during turn-off due to an optimized chip design and improved controllability. The decreased voltage helps minimize electrical stress on the IGBT and associated components, enhancing the overall reliability and robustness of the power module. Additionally, the X-Series FWDs incorporated in the HPnC modules are designed to have soft-reverse recovery characteristics. By lowering the peak reverse recovery current and its associated losses, this feature improves overall efficiency and reduces electromagnetic interference (EMI) in power conversion systems.

Robust Internal Construction & Low Internal Inductance

Reliability and robustness are essential factors in high-power applications, and Fuji has emphasized enhancing these aspects in their HPnC modules. One key element contributing to improved reliability is using a new high-performance insulating material, an insulating resin with a Comparative Tracking Index (CTI) greater than 600. This high-CTI resin provides excellent electrical insulation properties and reduces the risk of insulation breakdown in harsh environmental conditions.

HPnC modules utilize materials optimized to withstand extreme thermal cycling conditions. By incorporating ultrasonic-welded terminals and a choice of a MgSiC (Magnesium Silicon Carbide) or Cu (Copper) baseplate, the HPnC modules can endure many thermal cycles without compromising their structural integrity. For example, HPnC modules with a Cu baseplate can withstand up to 5,000 cycles at a temperature difference (ΔTc) of 80K in industrial applications.

In traction applications, where the thermal stress is even more demanding, HPnC modules with a MgSiC baseplate can endure up to 12,500 cycles at a ΔTc of 90K. This thermal cycling capability ensures long-term reliability and reduces the risk of premature module failure. With an inductance of just 12.5 nH, approximately 70% lower than a typical HPM, HPnC modules also minimize the impact of stray inductances. Moreover, their low inductance design allows the modules to achieve faster switching speeds, reduces overshoot voltages, and minimizes the risk of electrical noise and EMI issues.

Comparative Analysis: HPnC vs. High-Power Modules

This section presents a comparative analysis of HPnC modules concerning standard High Power Modules (HPM), Infineon’s PrimePACK™ modules, and the Mega Power Dual modules.

For package sizing, HPnC modules offer a more compact footprint of 99.5mm x 144mm, which is significantly smaller than the typical 130mm x 140mm and 140mm x 190mm packages used in typical HPMs. While the PrimePACK™ modules have a slightly smaller package size of 89mm x 250mm, the HPnC modules balance compactness and power density. The Mega Power Dual modules have a package size of approximately 130mm x 150mm.

Another benefit of HPnC modules is their weight reduction. Compared to conventional HPMs, HPnC modules are approximately 27% lighter. This weight reduction contributes to simplified mechanical design, reduced system-level costs, and improved power density. The lighter weight of HPnC modules allows for compact heatsinks and mounting structures, contributing to space savings and cost reduction in power conversion systems.

Thermal cycling capability is a critical factor in high-power applications, as it directly impacts the long-term reliability and lifetime of the power modules. HPnC modules exhibit superior thermal cycling performance, surpassing the other modules. When equipped with a Cu-baseplate, HPnC modules can withstand up to 5,000 cycles at a temperature difference (ΔTc) of 80K due to a high CTI > 600. In comparison, HPM and PrimePACK™ modules have a CTI > 400, withstanding 3,000 cycles at the same ΔTc, while Mega Power Dual modules endure up to 4,000 cycles.

Key Applications

Fuji’s HPnC modules are designed to cater to a broad range of applications, offering customers the flexibility to utilize them in various industries. Key applications include traction inverter, UPS, industrial drive systems, and renewable energy installations.

In traction inverter applications, like those found in locomotives, EVs, and off-highway vehicles, HPnC modules offer high performance and reliability. The modules’ high power density and low-loss design of efficient, compact traction inverters help reduce the overall system size and weight. Moreover, the high thermal cycling capability of HPnC modules equipped with a MgSiC baseplate ensures long-term operation and minimizes the risk of costly downtime.

Renewable energy systems, including solar power conditioning systems (PCS) and wind turbine converters, can also benefit from Fuji’s HPnC modules. The small footprint and low inductances of HPnC modules allow you to design high-power, high-efficiency inverters and converters for renewable energy applications. The simplified paralleling capability of HPnC modules is particularly advantageous in large-scale solar and wind installations, where multiple modules are often required to achieve the desired power ratings. By reducing the complexity of system design and installation, HPnC modules can speed up deployment times and lower costs in renewable energy projects.

Uninterruptible power supplies (UPS) are another key application where HPnC modules can be applied. The lower losses and high thermal cycling capability can improve UPS efficiency and reliability. The compact size of HPnC modules also enables the design of more space-efficient UPS, which is crucial in data centers and industrial environments where floor space is at a premium.

In industrial drive applications, such as manufacturing, material handling, and HVAC systems, Fuji HPnC modules offer a combination of high efficiency, reliability, and performance. Their low losses and fast switching capabilities allow users to design more efficient and responsive drive systems. The high reliability and thermal cycling of HPnC modules with a Cu baseplate ensures long-term operation and reduced maintenance requirements in industrial environments.

Conclusion

With their compact sizes, low inductance, improved electrical characteristics, and high reliability, Fuji Electric’s 7th-Gen HPnC modules allow you to design more efficient, space-saving, and cost-effective power conversion systems. These products offer customers the flexibility to scale their power solutions to meet the demands of various industrial-scale applications.

For more information on Fuji Electric’s 7th-Gen HPnC modules or application-specific inquiries, please visit the website or contact Fuji Electric’s sales team.