Directly mounting an IGBT module to a heat sink is feasible, though the mounting requires careful attention and consideration to ensure an optimal thermal interface to ensure effective heat dissipation and long-term reliability. Here are the key points to consider when mounting an IGBT module on a heat sink:

Thermal Interface Material (TIM)

- Thermal Paste or Pads: It’s essential to use an appropriate thermal interface material between the IGBT module and the heat sink. The thermal interface material fills any air gaps caused by microscopic surface irregularities of the IGBT and heat sink, enhancing the thermal contact and improving heat transfer. Thermal paste material is the most common due to its higher thermal conductivity, though thermal pads can also be used if ease of installation and repeatability is a consideration.

Mechanical Mounting

- Pressure and Evenness: The IGBT module must be securely mounted to the heat sink with the correct and even amount of torqueing. Over-tightening the mounting screws can warp the module or crack the internal ceramic substrates, while under-tightening may result in poor thermal contact. It is important to follow the manufacturer’s recommended torque settings.

- Spring-loaded Screws or Clips: These can provide consistent pressure and accommodate thermal expansion differences between the IGBT module and the heat sink, reducing mechanical stress.

Surface Preparation

- Clean and Smooth Surfaces: Ensure that both the heat sink and the IGBT module surfaces are clean, smooth, and free of debris or oxidation before assembly. Even small particles can create air gaps that significantly impede thermal conductivity and degrade heat transfer.

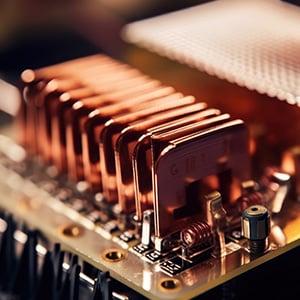

Heat Sink Design

- Sufficient Cooling Capacity: The heat sink must be appropriately sized and designed to handle the thermal load of the IGBT module under all operating conditions. This involves considerations of the heat sink’s material, fin design, and whether active cooling, i.e., fans is required.

- Orientation: The orientation of the heat sink fins should be considered based on the airflow direction to maximize heat dissipation.

Environmental Considerations

- Corrosion Protection: In harsh environments, both the heat sink and the IGBT module should have adequate protection against corrosive environments & substances, which can affect thermal and electrical performance.

- Moisture and Contaminant Protection: Ensure that the environment does not expose the heat sink and IGBT to conditions that could lead to moisture ingress or buildup of conductive or corrosive contaminants.

Electrical Insulation

- Isolation: If the heat sink is part of a grounded or conductive assembly, ensure that the IGBT module is electrically isolated from the heat sink. Mounting an IGBT module to a conductive heat sink assembly will require an additional electrical insulating layer that should also possesses good thermal conductivity.

By carefully considering these factors, one can effectively directly mount an IGBT module on a heat sink, ensuring efficient thermal transfer, heat dissipation, and reliable operation. Always consult the specific guidelines provided by the IGBT manufacturer, as the recommendations can vary based on the module’s design and materials.