Download the article | Watch Video Datasheet

Fuji Electric’s new X-Series RC-IGBT technology enables a higher power rating in the Dual.XT IGBT module from ratings of 800A-1200V to 1000A-1200V & 600A-1700V to 800A-1700V in the existing module package. The technology makes it possible to replace the high-cost, large-form-factor PrimePACK™ modules in power electronic systems.

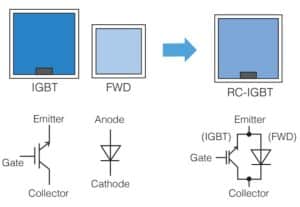

Figure 1. The RC-IGBT chip schematic and equivalent circuit.

Source: Fuji Electric

This article shows how the Fuji Dual.XT Module with RC-IGBT technology (see Figure 1) meets the most pressing needs of power semiconductors and includes a list of benefits and a summary of applications.

Power Semiconductors: What’s Needed?

Among the needs of power semiconductors, the miniaturization of power conversion systems is high on the list. Engineers are also seeking reduced costs and increased performance wherever possible. However, increasing the output power in a given package size leads to elevated temperatures, which is a risk factor for a shorter product lifetime.

The Solution: Fuji Dual.XT Module with RC-IGBT Technology

Fuji Electric’s RC-IGBTs integrate an IGBT and FWD on a single chip, using this technology and a 7th-generation X Series technology to create the line-up of the Dual.XT RC-IGBT modules with 1200V and 1700V ratings. Several critical aspects of this technology address the needs of modern power semiconductors.

Higher Performance

Implementing Fuji Dual.XT module with the reverse conducting (RC) technology expands the previous Fuji V-Series and increases the present X-Series generation’s power rating in the Dual.XT package. Figure 2 shows how the Fuji Dual.XT Module fits Fuji’s current offerings and increases the power density and overall performance.

Figure 2. The Fuji Dual.XT Module with RC-IGBT technology takes its place in the X Series Dual.XT lineup. Source: Fuji Electric

The 1000A-1200V Dual.XT module enables the replacement of 900A-1200V PrimePACK2, resulting in a more than 10% increase in module power rating.

Miniaturization and Integration

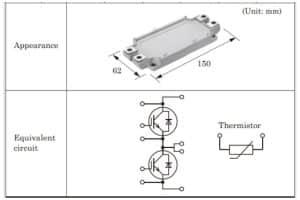

By combining the IGBT and FWD on a single chip, the RC-IGBT technology reduces the number of chips and the total chip area, further contributing to equipment miniaturization and a smaller bill of materials (BOM). The X-Series RC-IGBT modules were developed to facilitate the downsizing of power electronic systems. Figure 3 shows the electric circuit and appearance along with the 62-mm x 150-mm dimensions.

Figure 3. Appearance and equivalent circuit for the Dual.XT Modules.

Source: Fuji Electronics

Mitigation of Heat Generation

The Dual.XT module with RC-IGBT technology achieves excellent heat dissipation using a high-performance ceramic insulating substrate made of aluminum nitride (AlN). In addition, by integrating the IGBT and FWD functions on one chip, the RC-IGBT has a larger heat dissipation area than either an IGBT or FWD alone (compared with conventional IGBT + FWD systems at the same rated current).

Not only are thermal resistance and heat dissipation greater, but it is now possible to have higher-rated currents for the same chip area. The wire bonding was optimized, along with the use of high-strength solder and high-heat-resistant silicone gel. Note that the maximum junction temperature Tvj, max is between 150°C and 175°C.

Benefits of the Fuji Dual.XT Module with RC-IGBT Technology

Using the Dual.XT Module with RC-IGBT technology has several benefits, including improved performance and efficiency, higher reliability, ease of use, miniaturization, and greater power density.

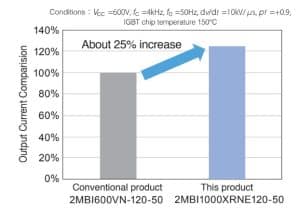

Better Performance

The prior V-Series Dual.XT RC-IGBT module rating of 600A-1200V was increased to 1000A-1200V, leading to a higher rating in the same package. Figure 4 shows that the output current at the stated conditions has been increased by 25% compared with conventional products.

Figure 4. Output current comparison during steady-state continuous operation.

Source: Fuji Electronics

Improved Efficiency

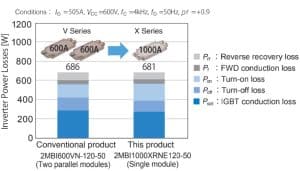

As an example of improved efficiency, the RC-IGBT enhanced Dual.XT modules can replace two 600A modules in parallel with a single 1000A module in a 350kW inverter. This contributes to equipment miniaturization and reduces the number of gate drivers as well as the inverter loss.

Figure 5. 350kW inverter loss comparison.

Source: Fuji Electric

Higher Reliability

The thermal capability designed into the Dual.XT RC-IGBT modules contributes to reliability and product life. The design considerations lead to a maximum junction temperature (Tvj, max) during operation from 150°C to 175°C, with more minor temperature fluctuations while ensuring high reliability.

Ease of Use

Because the Dual.XT module with RC-IGBT technology is available with solder pins and press-fit pins, it is easier to install and more flexible in its potential applications.

Miniaturization

The Dual.XT RC-IGBT modules offer a smaller footprint (9,300mm2 compared with 15,308mm2 for similar products) and a lighter weight (typically 250 grams compared with 850 grams). Thus, a higher power rating is achieved in a significantly smaller package.

Greater Power Density

The increased current and voltage ratings while maintaining the same or smaller package size means these chips have higher power density than similar products on the market.

Applications

The Fuji Electric Dual.XT Module with RC-IGBT technology has numerous applications, including key markets like solar and wind power generation. The RC-IGBTs have been optimized for industrial applications, emphasizing upward compatibility with conventional IGBT and FWD chipsets. They are commonly used for everything from motor drives to uninterruptible power supplies.

Conclusion

For power engineers struggling to find a high-density power module solution that supports increased performance, miniaturization, reduced chip count, and mitigation of heat generation, look no further than the Fuji Dual.XT module with X-Series RC-IGBT technology. To learn more, contact Fuji Electric today.