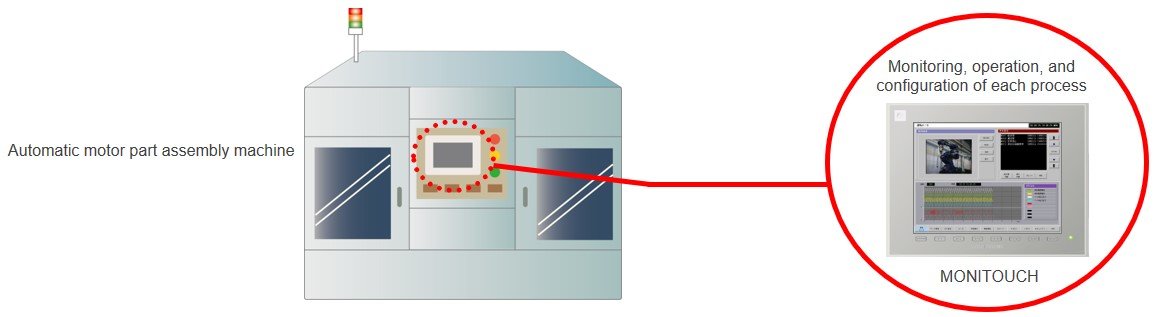

MONITOUCH installed on an automatic part assembly machine comprising a part feeder (alignment and supply of parts), pick-and-place unit (picking up and transferring workpieces), spot welder (welder that utilizes electrical resistance) and turntable.

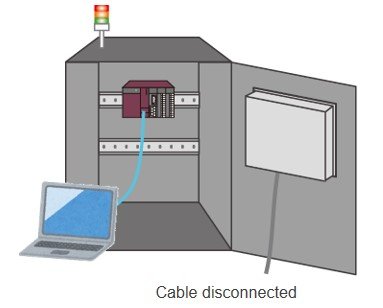

Before

When checking PLC circuits and changing ladders during machine maintenance, it’s a nuisance connecting a PC to the PLC since in many cases the PLC is installed at the rear of the panel. If the touch panel is connected via the CPU port, disconnecting the cable and connecting it to the PC is a nuisance.

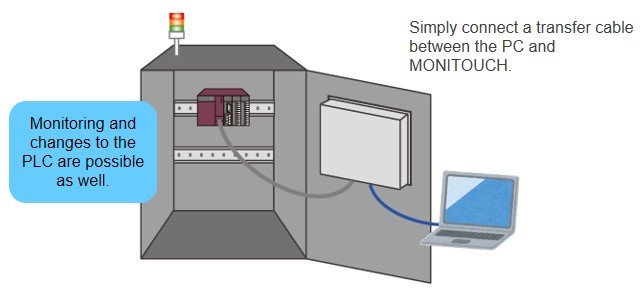

After

By using the MONITOUCH ladder transfer function, it is possible to check and change ladders by connecting a PC to the V9 while leaving the cable between the PLC and V9 connected.

Work can be performed with ease and without having to connect a cable from the PC to the rear of the panel.