MONITOUCH installed on an automatic part assembly machine comprising a part feeder (alignment and supply of parts), pick-and-place unit (picking up and transferring workpieces), spot welder (welder that utilizes electrical resistance) and turntable.

Before

Frequent management and changes to parameters for each part increases the complexity of PLC processing and decreases the machine performance.

It is crucial that automatic assembly machines perform tasks such as: Cycle processing with speed and constant efficiency which meant a system that reduces the PLC load.

After

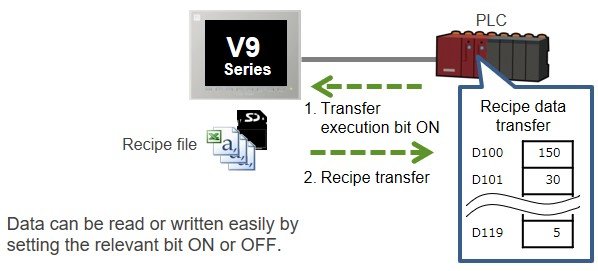

By using the MONITOUCH recipe function, data can be read or written with ease.

Setting the relevant bit to ON enables recipe reading and writing to be performed reliably, regardless of the screen display state, and reduces the PLC load. Recipe data can be stored in CSV files on a storage device connected to MONITOUCH.