MONITOUCH installed on plastic injection molding machines sold in Japan and overseas that form plastic products by melting plastic resin material, pouring the material into a die injection, and hardening the material into shape.

Before

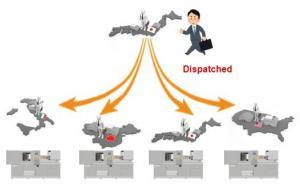

If trouble occurs on a machine, an employee must be sent to the machine site because the local situation cannot be accurately determined.

This leads to significant losses in terms of expenses and time, and increases costs.

After

By connecting MONITOUCH to a VPN server, PLC ladder programs and the MONITOUCH screen of each machine, site can be monitored from the maintenance service base. This way, the local situation can be analyzed and the time and expenses for dispatching employees can be reduced.