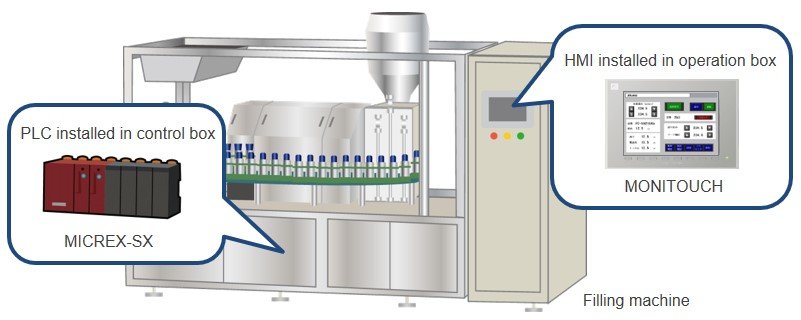

Filling machines fill containers and bags etc., with liquid or solid matter, such as drinks, oils, or medicines, and are widely used in the three industries: Food, pharmaceuticals, and cosmetics. Depending on the manufactured product, these machines can be very large.

Based on the characteristic of products to be manufactured and taking sanitation into account, filling machines are designed so they can be washed down with water.

In most cases, the PLC, which doesn’t mix well with water, is installed in a control box and the HMI is installed in an operation box. This means these devices are installed at separate locations.

From a security viewpoint, there are increasing cases of needing to fill out troublesome paperwork to bring a PC onto the factory floor.

Before

Customer A: We need to check the PLC program while viewing the HMI screen.

But this is difficult since the PLC and HMI are at separate locations.

Customer B: Recovery work is required since a major fault occurred at the factory.

However, since we don’t have the PLC software, the cause of the fault is unknown and recovery is impossible.

After

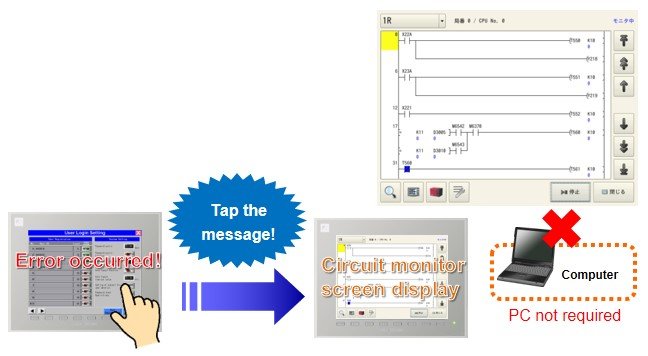

By using the MONITOUCH ladder monitor function, I/O checks on the PLC and identifying the cause of faults can be performed without bringing a PC onto the factory floor.