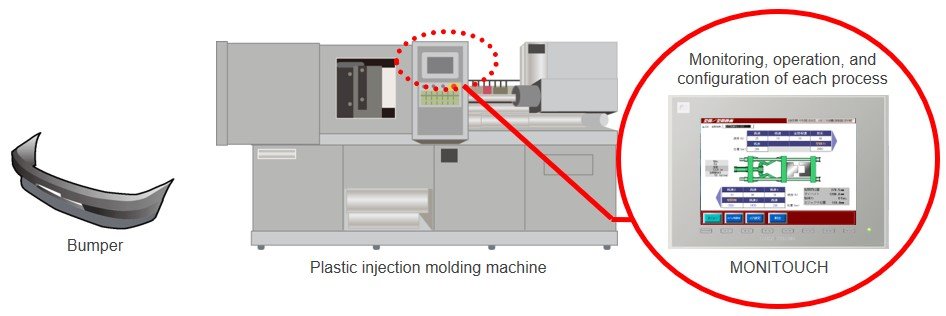

MONITOUCH installed on a plastic injection molding machine that forms plastic products by melting plastic material (resin), pouring the material into a die (injection), and hardening the material into shape.

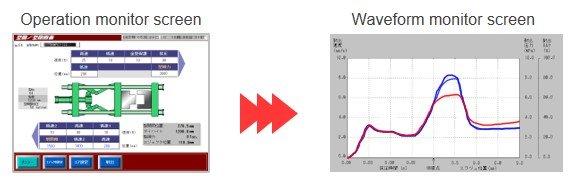

Before

Product quality is checked by overlaying a trend graph (real-time display) of the injection status on the waveform monitor screen.

When returning to the waveform monitor screen after displaying the operation monitor screen, overlaid trend graphs disappear. This means that subsequent quality checks cannot be performed and recognizing changes in quality becomes difficult.

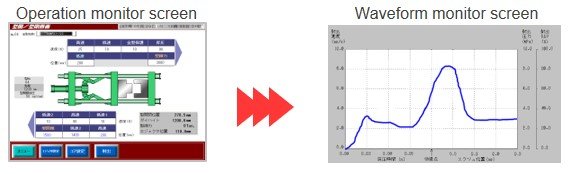

After

By using the trend graph function (real-time display) as a background operation, the screen overlaid with trend graphs can be updated allowing variations in production to be noticed using statistical process control (SPC). This has enabled prevention of releasing defects.