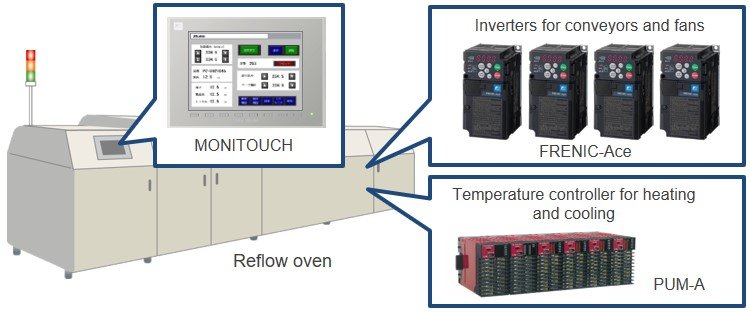

A reflow oven is a machine used to mount IC components onto the surface of printed circuit boards. Components are soldered by first placing components and solder paste on boards, melting the solder paste by applying high temperature and then cooling

- Reflow ovens contain many inverters for conveyors to transport boards and fans for heating and cooling.

- Reflow ovens employ a temperature controller for adjusting the temperature to melt solder at high temperatures and to perform cooling.

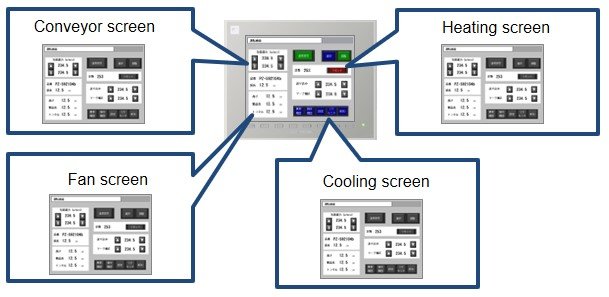

- Reflow ovens require frequent reconfiguration of the temperature controller and inverter settings due to different temperature profiles of boards for processing.

Before

After machine assembly, various data setting must be changed from the factory settings to the actual operation settings. However, there are many parameters and creating dedicated screens for each station number difficult.

After

The V-SFT screen configuration software provides component parts for inverters and temperature controllers.

Settings screens can be created by simply placing parts and setting station numbers. Placement of multiple parts is also supported (up to 16 parts per screen).