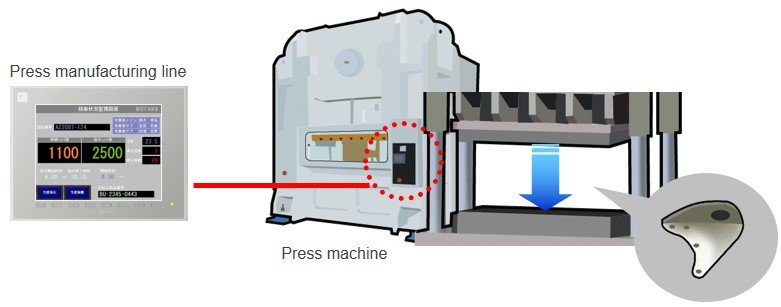

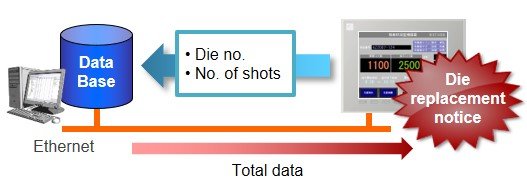

MONITOUCH installed on a press manufacturing line and linked to a database to construct an operating management system (MES) that acquires die and shot information.

Before

Since the die used on the press machine deteriorates with production cycles, periodic maintenance is required to maintain a constant level of product quality.

- This causes data management to be inefficient and difficult to be managed.

- Employees often forget to perform maintenance and end up with defective products.

After

By using the MES function, it is possible to compile a database of records on shot information. Creating a separate program (Macro) on MONITOUCH allows notifications of replacement periods by tallying data in the database.

Even if an increase of machines on the line becomes necessary, layout changes can be handled easily without needing to contact the system manager because settings on the upstream server do not need to be changed since control is performed by the MONITOUCH installed on each machine.