Pharmaceutical Manufacturing HMI Units and Instrumentation

Fuji Electric plays an important role in Pharmaceutical Manufacturing as our Instrumentation and HMI Display products are utilized in the field’s operations. Scroll down to view which Instrumentation & Control and HMI products are right for you.

Instrumentation & Control

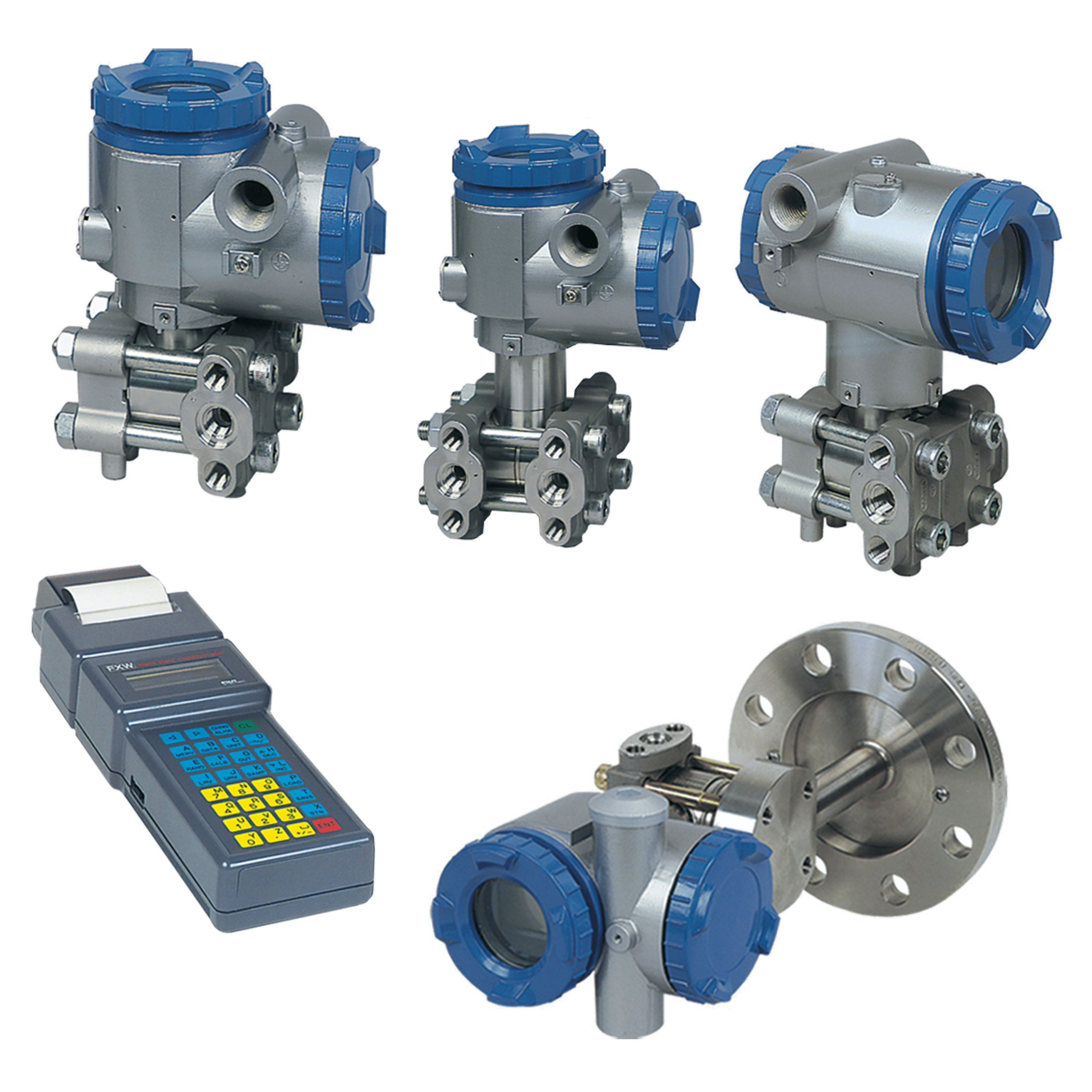

Fuji Electric manufactures flow meters and pressure transmitters with a limit over 21,000 psi for drilling, as well as differential pressure transmitters for high pressure applications. Our flow meters can measure the flow for liquid, gas and other types of mixtures. Fuji Electric’s differential pressure measurements can be used to measure the tank level for closed tanks and a gauge pressure measurement for open tanks. With a limit up to 21,000 psi, our pressure transmitters are explosion proof and custom made in-house for quick turnaround and delivery.

Benefits of Fuji Electric Instrumentation & Control Products:

- Pressure Transmitters – Used for pressure and flow measurement

- Flow Meters for Fluid – Made use for energy conservation and leak detection; ideal for flow surveys, verifications, and energy/BTU measurements

- Electromagnetic Flow Meters – Results measurements are independent of density, temperature and pressure

Instrumentation & Control for Pharmaceutical

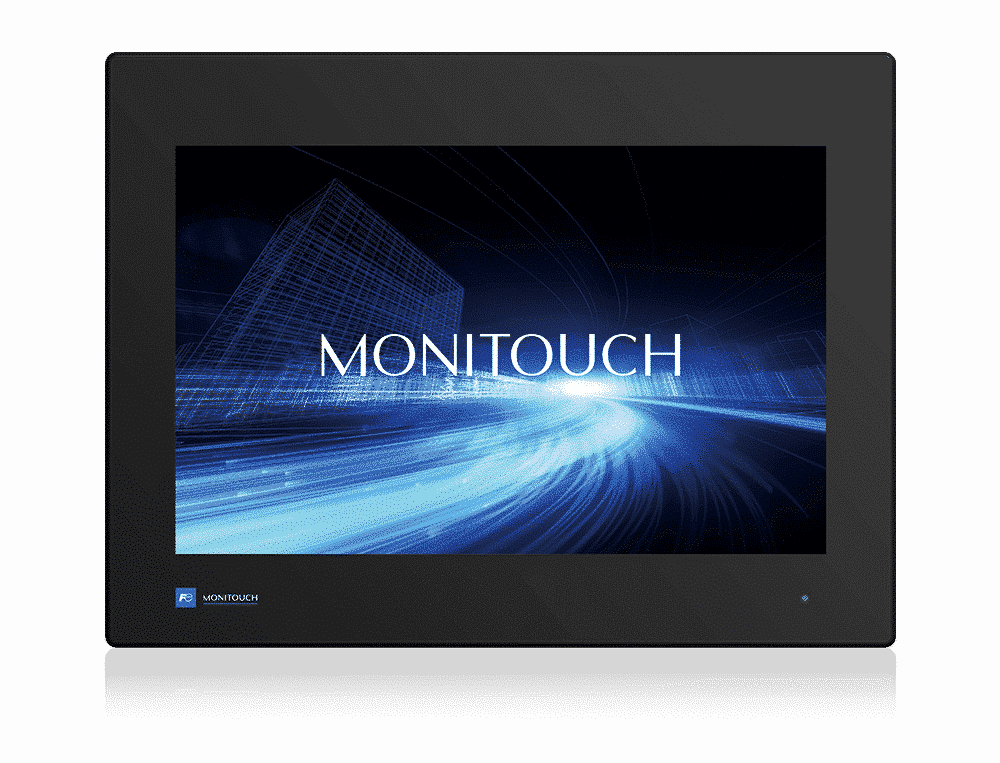

HMI Units

Fuji Electric has manufactured original human machine interface (HMI) units since 1988 and provided solutions for the Pharmaceutical industry to increase efficiency and quality improvement. From operation log function, recipe function, 8-way communication and JPEG display, our HMI units can be utilized for a multitude of functions within this market segment. These HMI displays allows customers the ability to interface via a cellphone network to troubleshoot, are compatible with other Fuji products and reduces wiring of hard operating devices. Our V9 MONITOUCH HMI displays can be installed on a range of machines to improve efficiency when manufacturing parts or products for major OEMs. Our user-friendly V-SFT software is easy to use and allows multiple data management. By connecting to the cloud to analyze, visualize, and understand trends in collected data, we can improve the efficiency of production systems. In addition, by installing the X1 series in pharmaceutical equipment that requires advanced security management, it will contribute to ensuring security in pharmaceutical manufacturing.

V9 & Technoshot Features & Benefits:

- Operation Log Function – Allows viewing of the operation procedures that cause defects and production settings based on the date and time manufactured

- Recipe Function – Data can be read or written with ease; Recipe data can be stored in CSV files on a storage device connected to MONITOUCH

- PLC 8-Way communication – Programs for connection and control are not required and number of units can be reduced

- MES Function – Creating a separate program (Macro) on MONITOUCH allows notifications of replacement periods by tallying data in the database

- Device Memory Map – Reduce the work hours required to create transfer programs. Improved operation responsiveness

New X1 Features & Benefits:

- Cloud (MQTT) Compatible – Contributes to the visualization and improvement of the factory; various tools and frameworks of the cloud service can be used

- OPC UA Server and Client – Enables data sharing between production sites and the host system, and facilitates the standardization of equipment

- Security Function – Screen display and operation can be restricted according to the security level

- Vector Graphics – Enable high quality and tailored screen creation as it allows the enlargement/reduction of parts while maintaining a clear image

- Application Alignment – This function helps you to switch multiple application windows easily and improves operability

HMI Displays for Pharmaceutical