Double Beam NDIR Gas Analyzer (ZKJ)

Simultaneous and continuous measurement of up to 5 components among:

NO, SO2, CO2, CO, CH4, N2O, and O2

Ideal for flue gas monitoring in incinerators and industrial furnaces

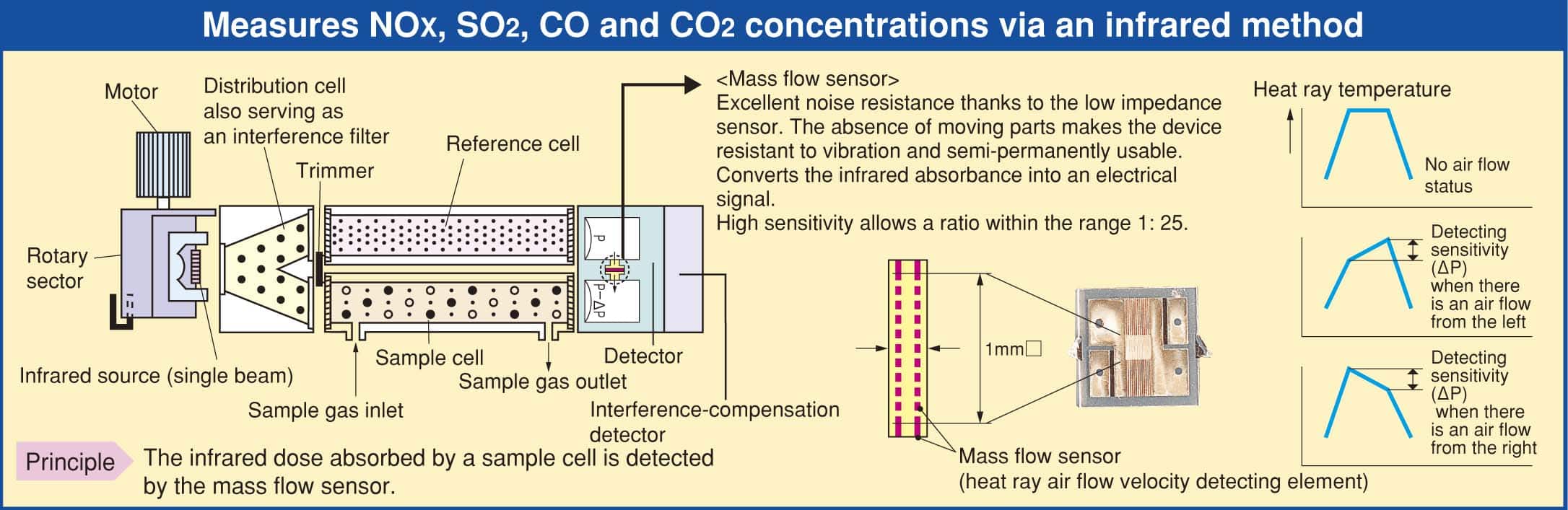

- The mass flow type twin detector — hardly affected by interference gas

- A variety of functions: auto calibration, O2-corrected output, averaging, alarm, etc.

- Easy-to-see LCD

You can check the concentration changes of all components at a glance - 19-inch rack mount

- Maximum range ratio 1 : 25

A user can set or change a range within the limit - Zero drift for 200 ppm range: ≤ ±1% FS per week

Specifications

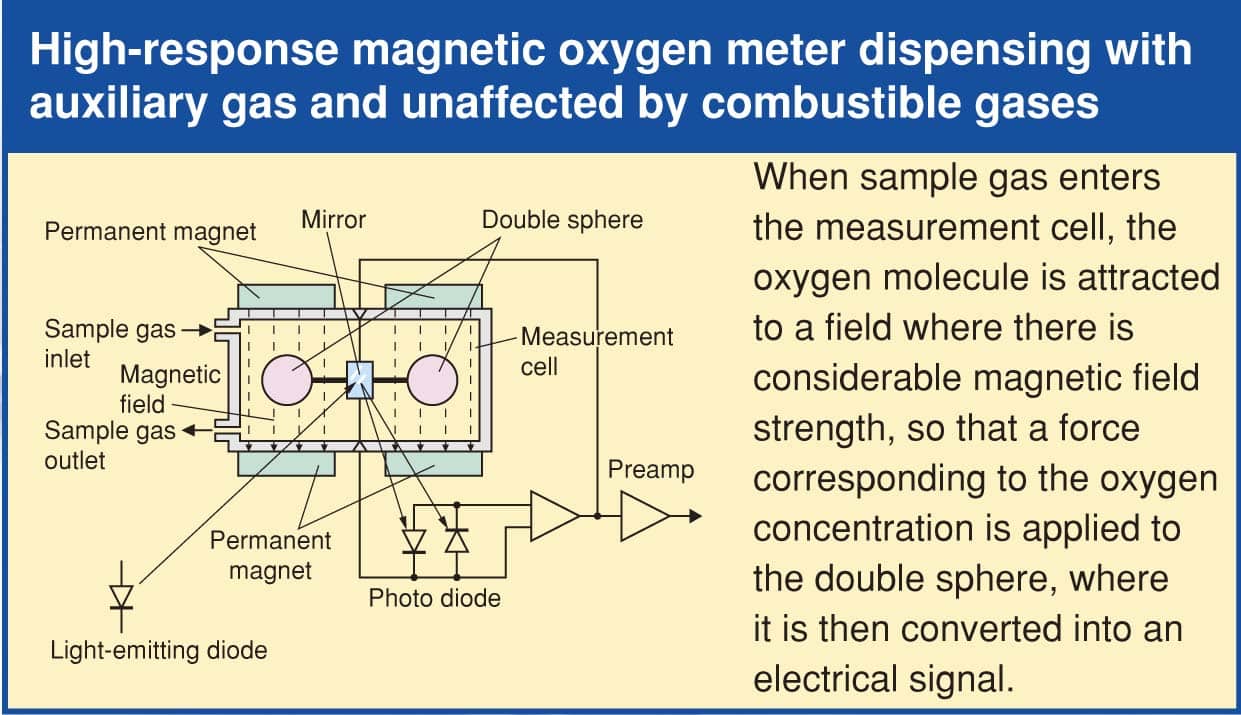

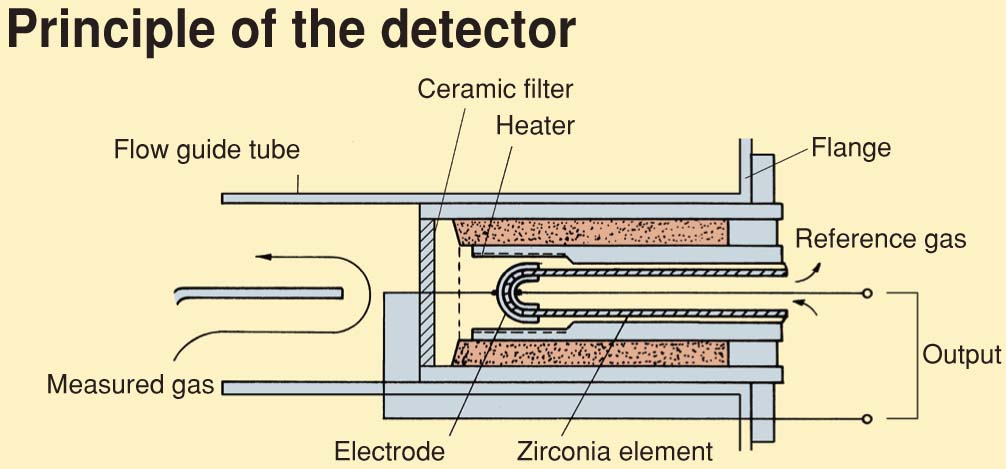

| Principle | NO, SO2, CO2, CO, CH4, N2O: Non-dispersive infrared sensor O2: built-in paramagnetic sensor or external zirconia sensor (ZFK7, optional) |

|

|---|---|---|

| Components | 1 component: NO, SO2,CO2, CO, CH4, N2O 2 components: NO + SO2, NO + CO, CO2 + CO, N2O + CO2 3 components: NO + SO2 + CO, NO + N2O + CO2, SO2 + N2O + CO2, N2O + CO2 + CO, CH4 + N2O + CO2 4 components: NO + SO2 + CO2 + CO , NO + SO2 + N2O + CO2 O2 measurement can be added to above all. |

|

| Range | NO: 0–50 ppm…5000 ppm SO2: 0–50 ppm…10% CO2: 0–20 ppm…100% CO: 0–50 ppm…100% CH4: 0–200 ppm…100% N2O: 0–200 ppm…2000 ppm O2: 0–5%…25% |

|

| Repeatability | ±0.5% FS (±1% FS for 50 ppm or less) | |

| Zero drift | ≥ 200 ppm range: ±1% FS per week 50–200 ppm range: ±2% FS per week ≤ 50 ppm range: ±2% FS per day |

|

| Span drift | ≤ ±2% FS per week (50 ppm or less: ±2.0% FS per day) |

|

| Linearity | ±1% FS | |

| Response time | ≤ 60 s (for 90% response) at a sample gas flow rate of 0.5 L/min | |

| Output signal | 4–20 mA DC or 0–1 V DC (instantaneous values, O2-corrected instantaneous values, O2-corrected average values, O2 average) |

|

| Contact output | Instrument error, calibration error, range identification, auto calibration status, pump ON/OFF, peak alarm, high/low limit alarm, power disconnection alarm | |

| Contact input | Remote range switch, auto calibration remote start, remote holding, average value resetting, pump ON/OFF | |

| Functions | Auto calibration, O2 correction, O2average, CO peak count and alarm, etc. | |

| Operating environment | -5 to +45°C, RH 90% or less | |

| Power supply voltage | 100–240 V AC, 50/60 Hz, 250 VA | |

| Dimensions | 483 (H) × 177 (W) × 600 (D) mm | |

| Gas conditions | Temperature | 0–50°C |

| Flow rate | 0.5 L/min ±0.2 L/min | |

| Pressure | ≤ 10 kPa (gas outlet should be open to the atmospheric air) | |

| Dust | ≤ 100 μg/Nm3 with particle size ≤ 1 μm | |

| Mist | Unallowable | |

| Moisture | Below the saturation vapor density at 2°C (Non condensing) | |

| Corrosive gas | ≤ 1 ppm | |

| Zirconia O2 sensor (to be purchased separately) |

|---|

ZFK7 |

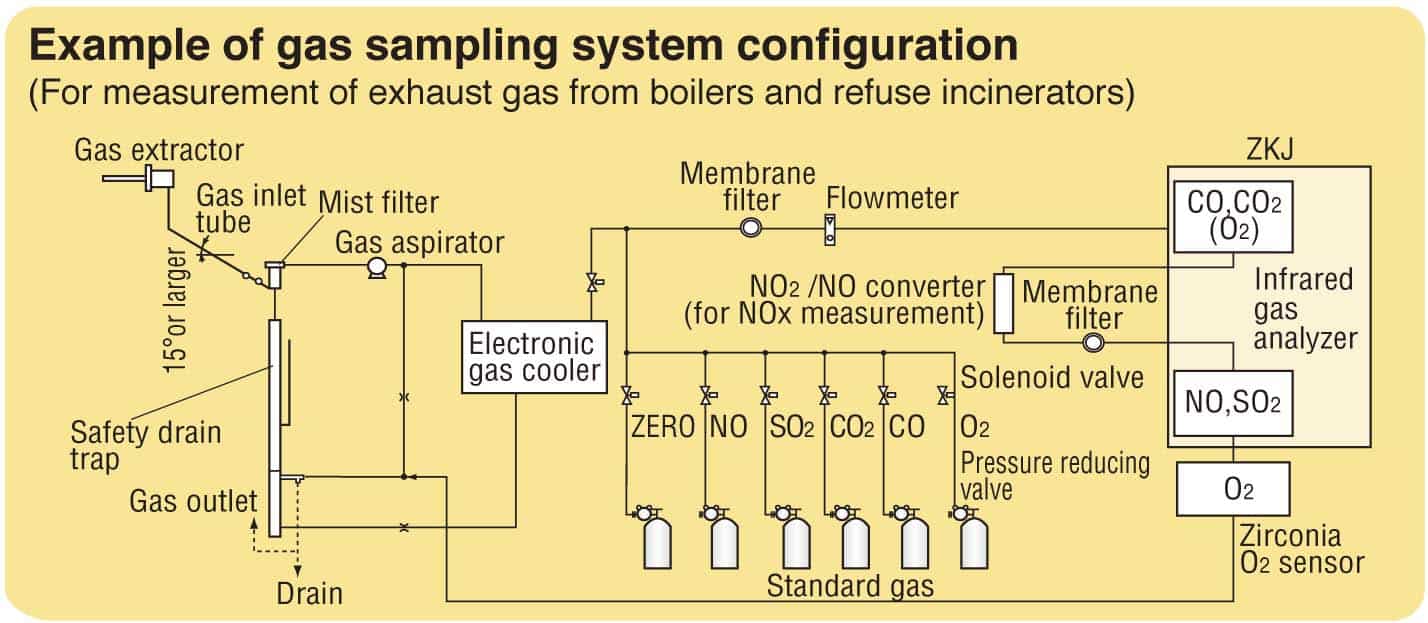

Gas sampling system configuration example

The following diagram shows a typical sampling system for monitoring five components in flue gas from boilers or incinerators. We can configure an ideal system for any application.