Flue Gas Analyzer System (ZSU)

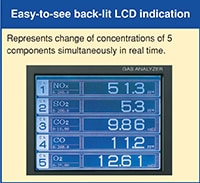

Continuous monitoring of up to 5 components:

NOx, SO2, CO, CO2, and O2

Ideal for flue gas monitoring in waste incinerators, boilers, and furnaces

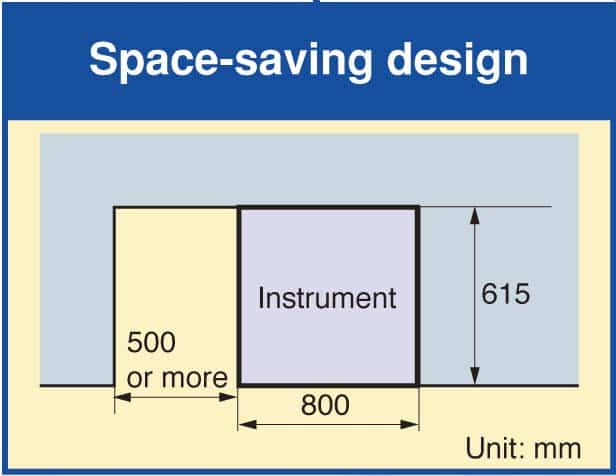

- Space-saving design

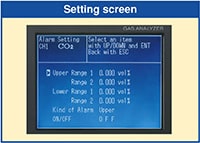

- A variety of functions: auto calibration, O2-corrected output, averaging, alarm, etc.

Specifications

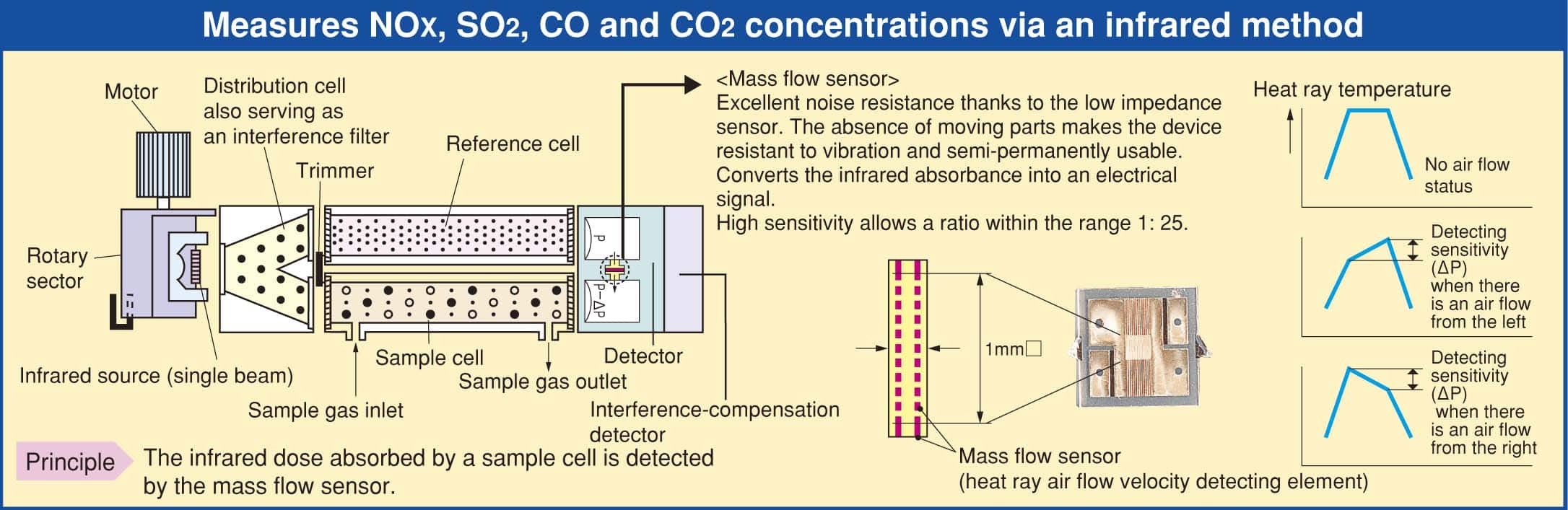

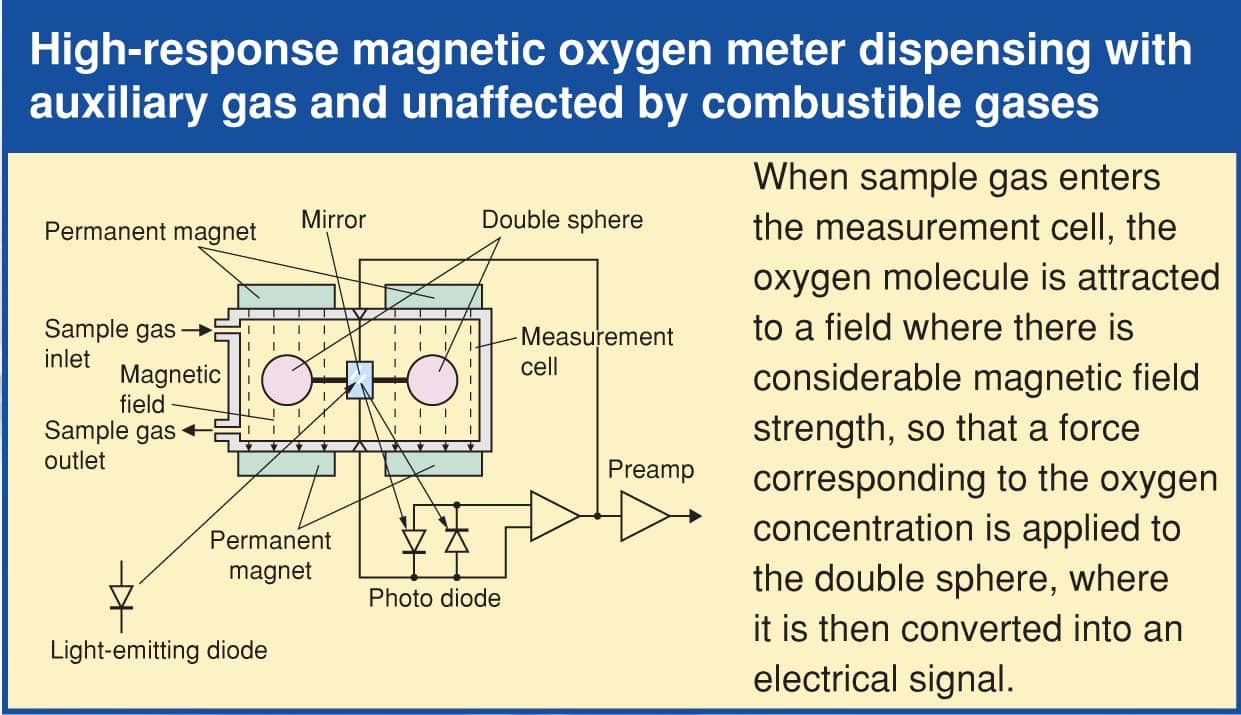

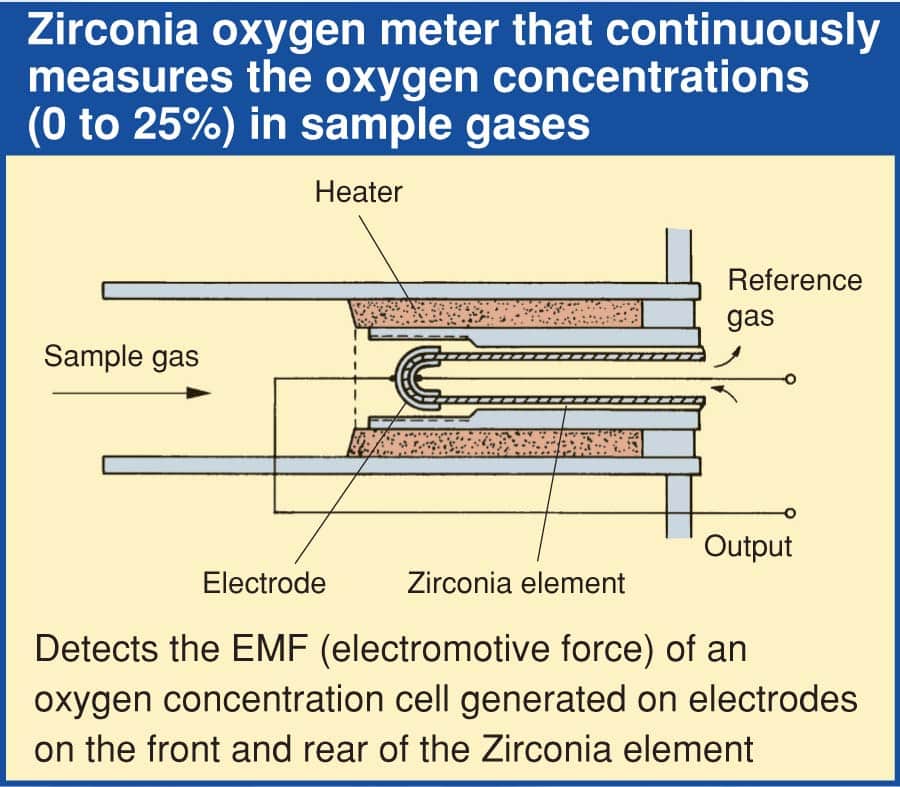

| Principle | NOx, SO2, CO, CO2: Non dispersive infrared sensor O2: zirconia sensor or paramagnetic sensor |

|

|---|---|---|

| Components | 1 component: NOx, SO2, CO, CO2 2 components: NOx + SO2, NOx + CO 3 components: NOx + SO2 + CO 4 components: NOx + SO2 + CO + CO2 O2 measurement can be added to above all. |

|

| Range | NOx: 0–50 ppm…5000 ppm SO2: 0–50 ppm…5000 ppm CO: 0–50 ppm…5000 ppm CO2: 0–10%…20% O2: 0–10%…25% |

|

| Repeatability | ±0.5% FS | |

| Zero drift | ≤ ±1.0% FS per week Ranges below 200 ppm: ≤ ±2.0% FS per week In O2 measurement: ≤ ±2.0% FS per month |

|

| Span drift | ≤ ±2.0% FS per week In O2 measurement: ≤ ±2.0% FS per month |

|

| Linearity | ±1.0% FS | |

| Response time | ≤ 120 s (for 90% response, from the analyzer inlet) ≤ 240 s for SO2 measurement |

|

| Output signal | • 4–20 mA DC (linear) (instantaneous values, O2-corrected instantaneous values, O2-corrected average values, O2 average) • Contact output (CO peak count and alarm, concentration alarm, under auto calibration, device error, etc.) |

|

| Contact input | Auto-calibration start, average reset, range switch, output hold, pump ON/OFF, etc. | |

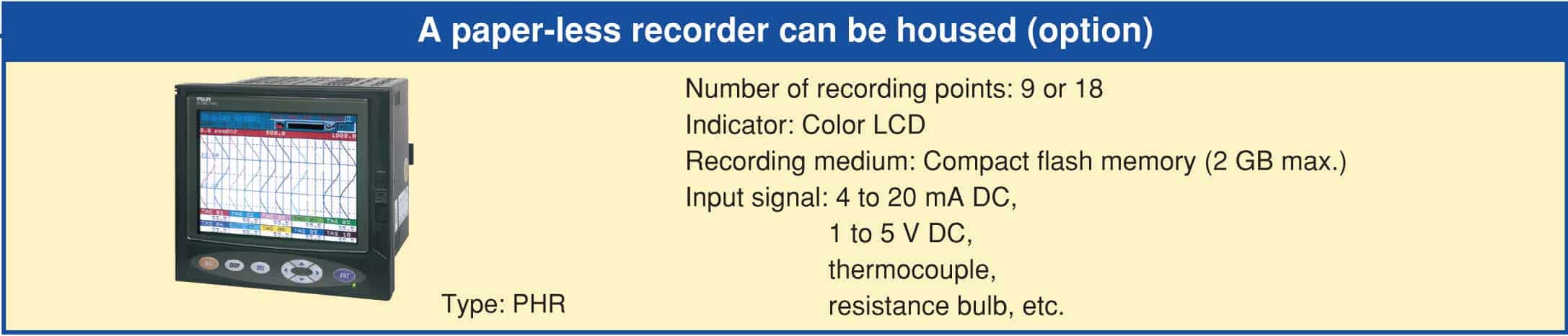

| Functions | Auto calibration, O2 correction, averaging, CO peak count and alarm, data recording | |

| Operating environment | -5°C to +40°C or -10°C to +40°C, RH 90% or lower | |

| Power supply voltage | 100, 110, 115, 200, 230 V AC, 50/60 Hz | |

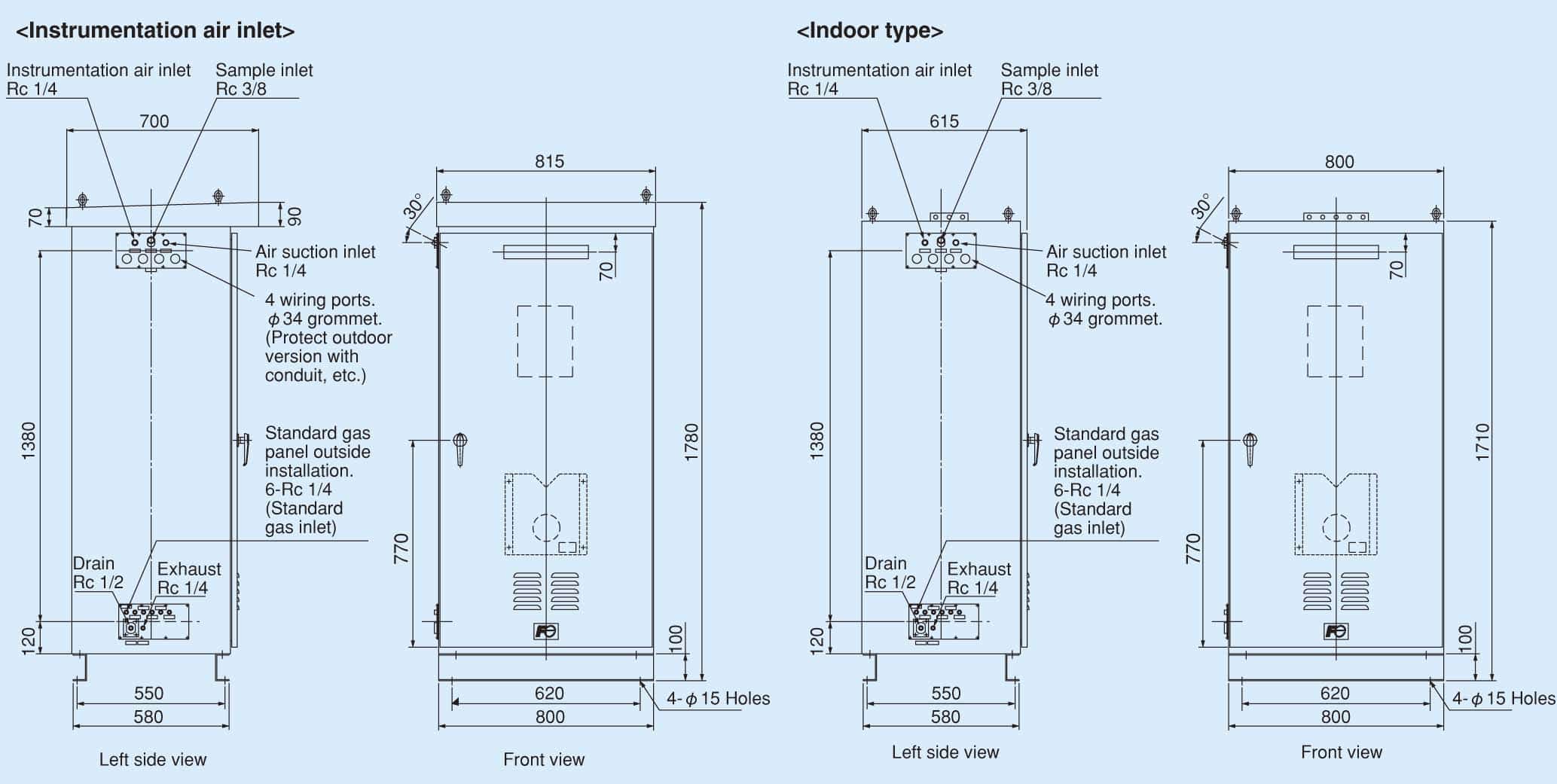

| Dimensions | 800 (H) × 1710 (W) × 615 (D) mm, for indoor use Houses six 3.4 L standard gas cylinders |

|

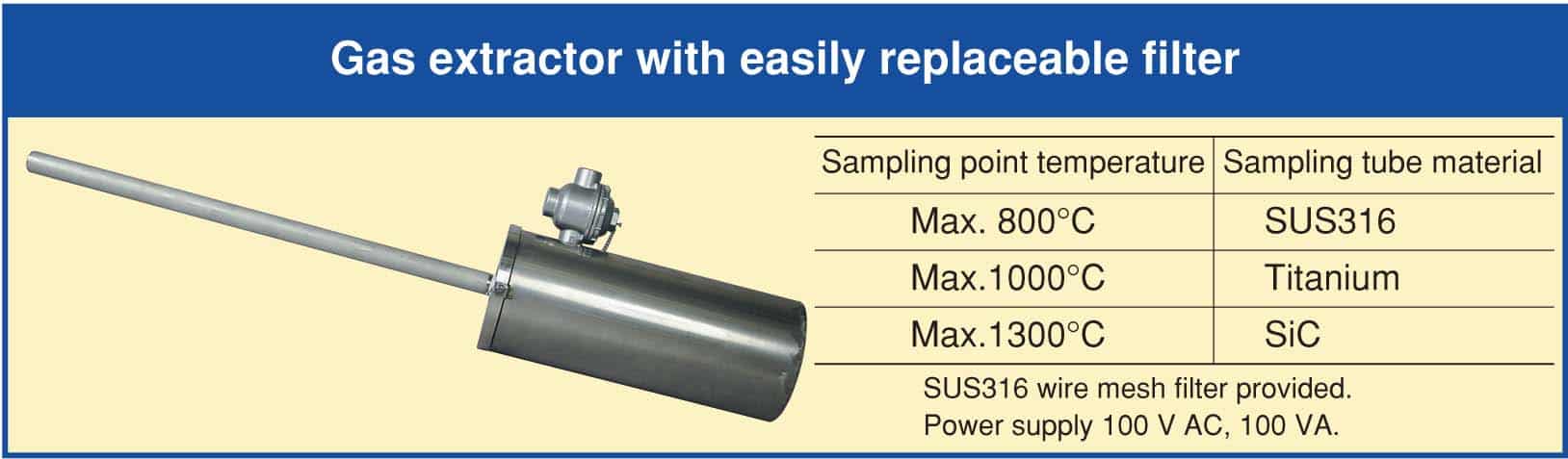

| Gas conditions | Temperature | Standard: ≤ 800°C Non-standard: ≤ 1000°C or 1300°C |

| Dust | ≤ 100 mg/Nm3 | |

| Pressure | -3 to +3 kPa | |

| Component | SO2: ≤ 500 ppm NOx: ≤ 1000 ppm CO2: ≤ 15% CO: ≤ 2000 ppm HCl: ≤ 1000 ppm |

|

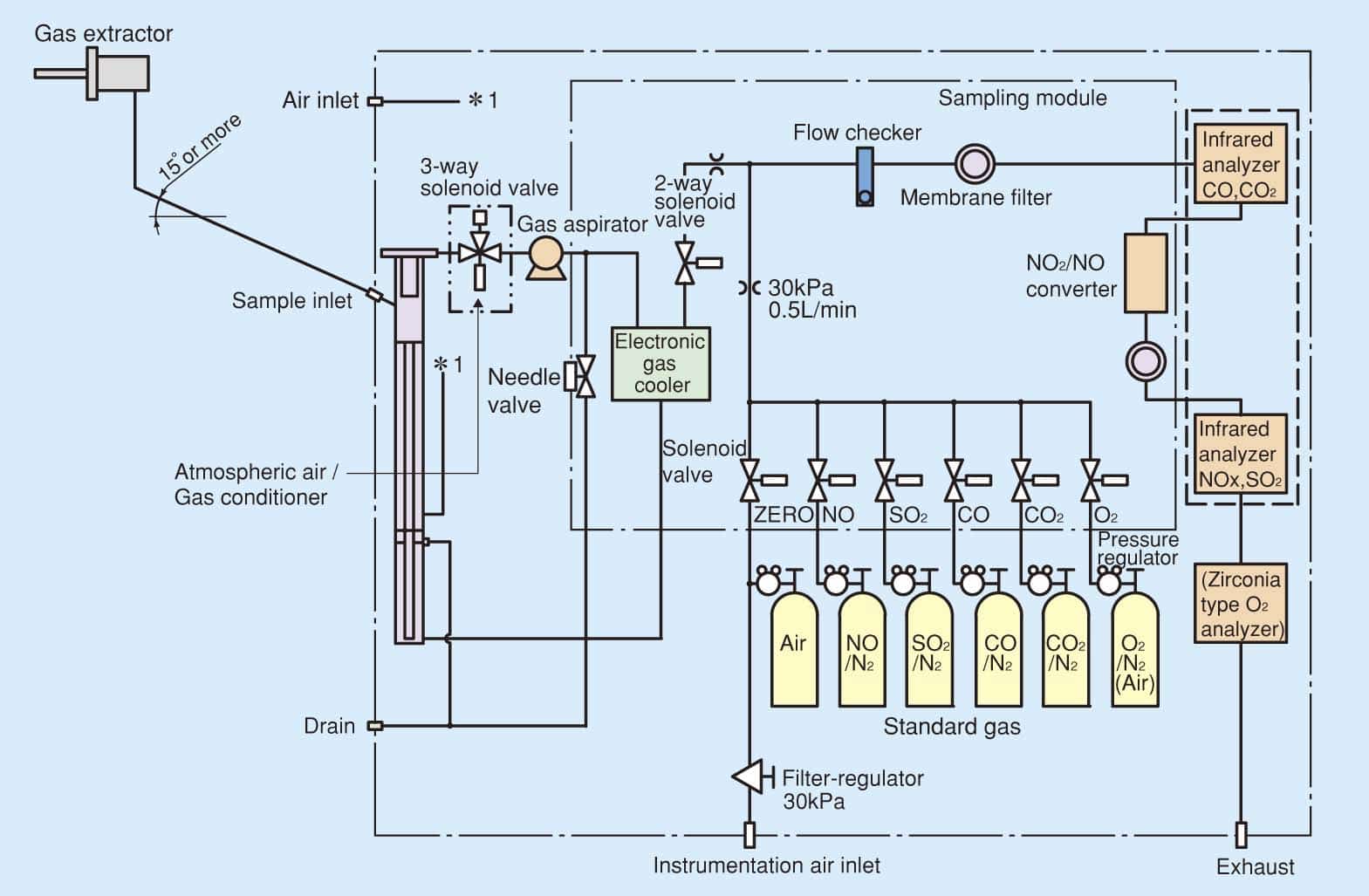

Gas sampling system configuration example

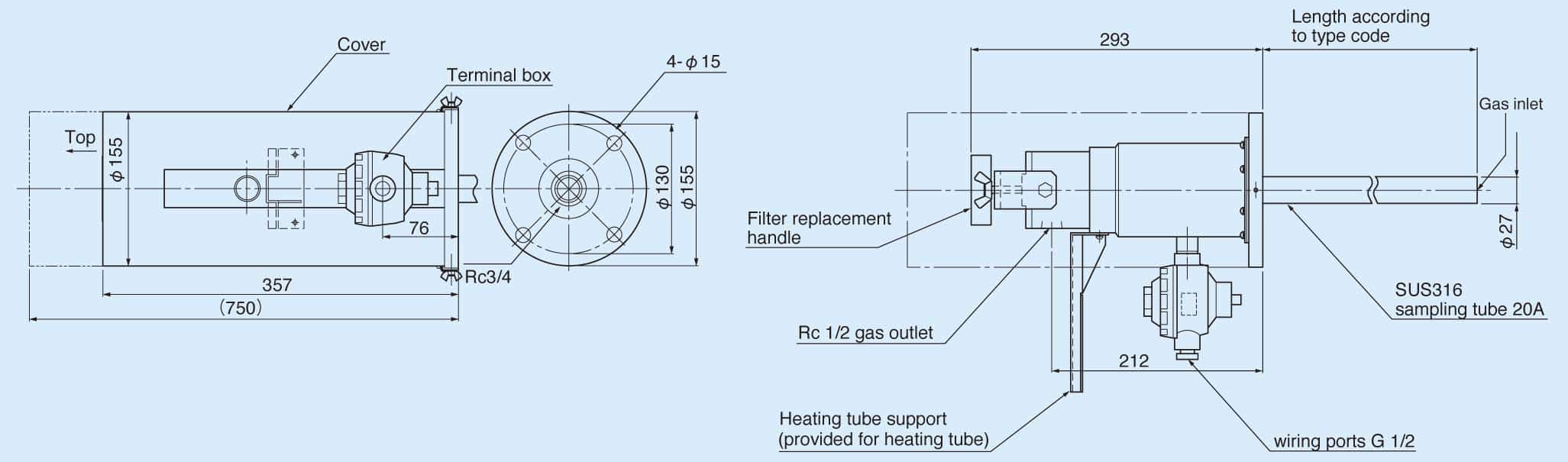

Dimensions (in mm)

Gas extractor dimensions (in mm)