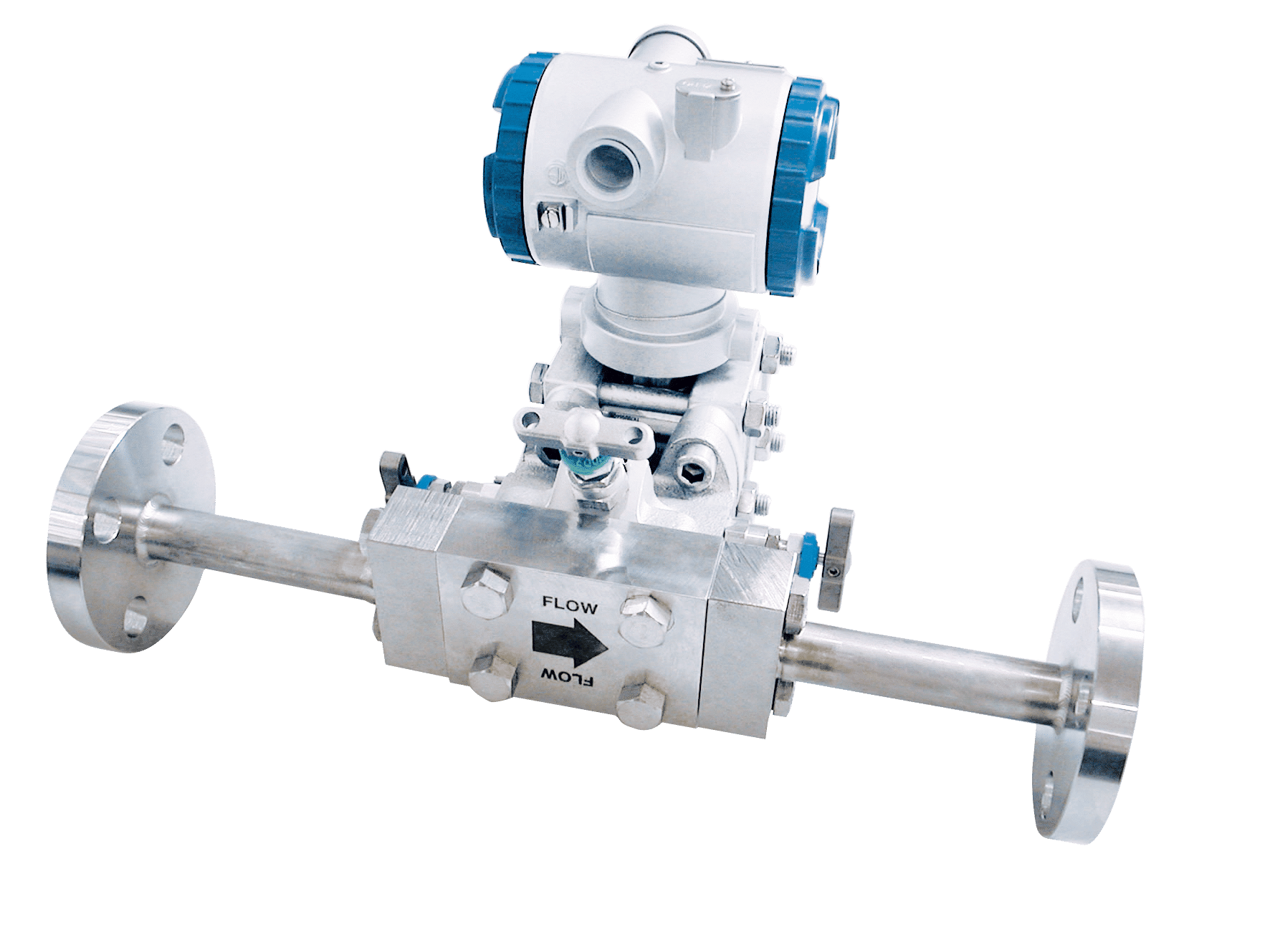

Integral Flow Orifice

for Liquid and Gas Flow Measurement

An integral orifice flow meter is a device used for measuring the fluid flow rate. It measures the volumetric flow rate and speed of liquid or gas as it flows through a pipe. It is a common instrument in the industrial process control industry.

Measure Low Liquid or Gas Flow Rates

Designed for safe and easy installation, the Fuji Electric integral orifice will measure very low liquid or gas flow rates in small bore pipes. It may be bolted directly to FCX DP transmitters or any pressure sensors that uses standard 54mm centres. The body is machined from a single-piece of 316 SS (or other material) to give high pressure integrity.

Advantages

The integral flow orifice assembly consists of an orifice plate inside the tube section in line with the main flow stream. A differential pressure transmitter is directly mounted on the orifice assembly. The main advantage is that it eliminates the installation cost with impulse pipes up to the orifice.

Unique Design

Its unique design incorporates the “Fuji Electric Slip-Ring” to hold the orifice section in place without the use of additional bolts or screws.

Six different sizes of orifice section can be fitted without using any special tools.

It is impossible for the orifice section to move out of place without removal from the pipeline.

This significantly increases safety over other designs.

Features

The complete assembly is fixed into the pipeline using standard oval flanges for easy maintenance. If a very high accuracy is required then the unit can be fitted into a metered run and flow calibrated as a complete assembly.

- Six sizes of interchangeable orifice section

- Measurement of very low flow rates, liquid or gas

- Simple and precise installation using 2 oval flanges

- Direct mounting onto DP transmitter

- Body machined from single-piece stainless steel

- Fuji Electric slip-ring locates orifice section without bolting

- Accuracy better than ±2% with flow calibration

- Ex-stock delivery

Specifications

Fluid: Clean liquids and gases compatible with the materials of manufacture.

Process Pressure: Vacuum to 160 BarG

Process Temperature: -40 to + 120 degC

Ambient Temperature: Depends upon transmitter

Body & Wetted Parts: 316 SS (see options)

Oval Flange: 316 SS

Bolts: Cr Mo alloy (630 SS optional)

Seals: Viton & PTFE

Process Connection: 1/2” NPT via oval flanges

Transmitter Connection: Direct mounting on 54mm centres

Transmitter Bolt Threads: M10 (7/16 UNF optional)

Oval Flange Bolt Threads: M10

Scope of Supply

Fuji Electric will supply the integral orifice assembly for fitting to the differential pressure transmitter or a complete system fully calibrated and ready for direct installation into the pipeline. Devices that may be fitted directly to the integral orifice assembly include dp switches, dp indicators and dp transmitters. 3-valve manifolds may be used with these devices to calibrate zero and enable removal while the line is under pressure. The dp transmitter can be supplied with square root extraction, analogue or digital indicator, HART communication, Exi, ExN or Exd hazardous area certification and/or NACE specification. For mass flow, gauge pressure transmitters, absolute pressure transmitters and temperature sensors can be built into a metered run and supplied complete with a mass flow computer. One instruction manual is supplied with each shipment. A full set of drawings and certificates can also be supplied.