Integral Ultrasonic Flowmeter S-Flow (FSZ)

Easy Installation, Space Savings

Flow rate is “visualized” using our long-cultivated ultrasonic technologies.

Contributes to energy savings and production process solutions.

- Easy Clamp-on type by simply tightening 4 screws.

No need for pipe modification. - Integrated detector and flow transmitter for space savings.

- Built-in temperature sensor enables simultaneous measurement of flow rate and temperature (Optional).

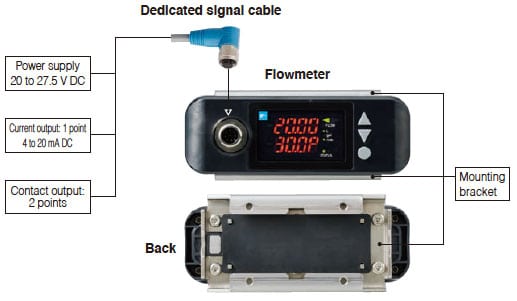

Equipment configuration

Integrates the detector and flow transmitter to simplify equipment configurations.

Features

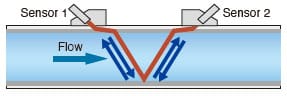

Measuring principle

Transit-time measuring method by Fuji proprietary digital signal processing

By using the ultrasonic pulses transmitted diagonally between the upstream and downstream sensors mounted on the outside of the pipe, the flow rate is measured by detecting the time difference obtained by the flow of fluid.

Reduces labor hours and installation costs

Clamp-on type requires no pipe modification. It can be installed without stopping equipment.

Easy installation using a single screwdriver.

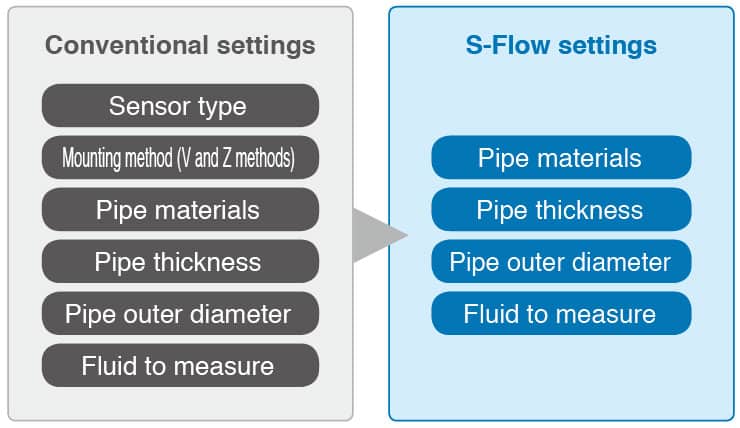

Easy to set up

Configurable only with three buttons. Simply turn on, configure four settings, and start measuring immediately.

No grease required

No need to store grease for maintenance purposes.

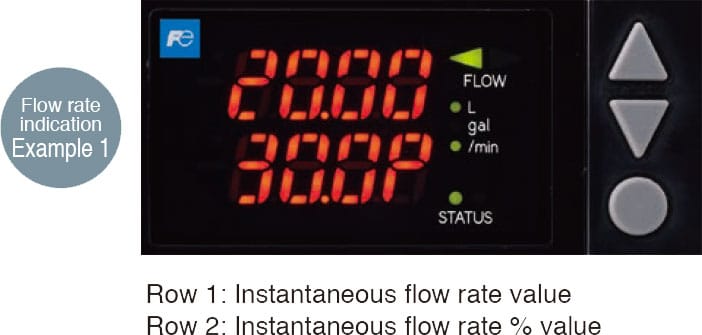

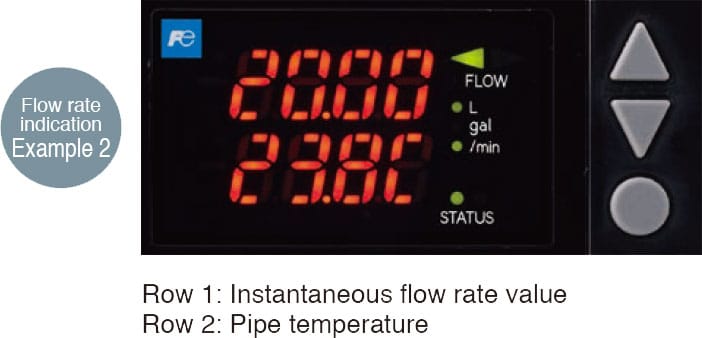

Easy-to-read LED display of flow rate values

Easy-to-read, intuitive 2-row LED display. Front function keys allow for easy operation.

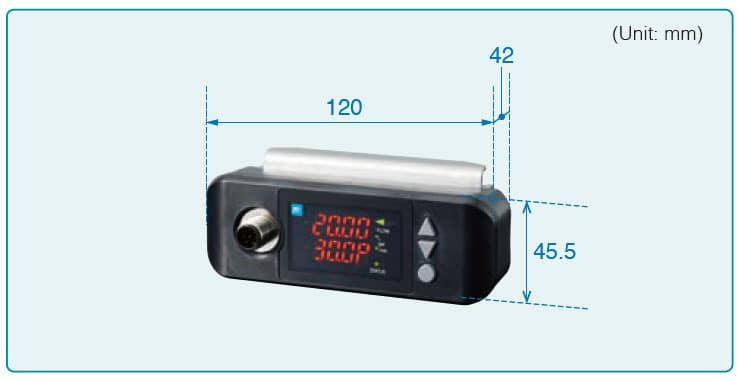

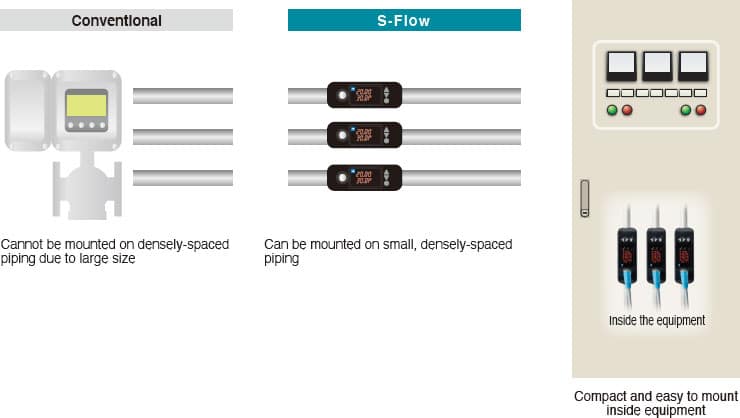

Integral, Compact design

Flow transmitter and detector functions are integrated to achieve compact dimensions. Compared to conventional flow transmitter (type: FLR), the size is reduced by approximately 76%.

Can be installed on densely-spaced piping and inside of equipment

Specifications

| Main unit type | Type | Pipe diameter |

|---|---|---|

| FSZ08 | 8A, 10A | |

| FSZ15 | 15A, 20A | |

| FSZ25 | 25A, 32A | |

| FSZ40 | 40A, 50A |

| Configuration | Integrated flow transmitter and detector |

|---|---|

| Mounting method | Clamp-on type |

| Measurement method | Transit-time measuring method |

| Fluid to measure | Homogenous fluids where ultrasonic signals can be transmitted |

| Measurement range | 0 to ±5 m/s (Min. 0 to ±0.2 m/s) |

| Accuracy | Velocity 1 m/s to 5 m/s: ±2% of rate Velocity less than 1 m/s: ±0.02 m/s |

| Required straight pipe length | Upstream 10D or more; Downstream 5D or more (D: Pipe inner diameter) |

| Pipe materials | Metals (stainless steel, steel, copper) Plastics (PVC, PP, PVDF) |

| Piping thickness | 1.2 mm to 4.9 mm |

| Fluid temperature | -15 to +85°C (Can vary depending on ambient temperature) |

| Response time: | 0.5 seconds |

| Output signal | 4 to 20 mA DC: 1 point Contact: 2 points |

| Display | LED 4-digit 2-row display |

| Degree of protection | IP65/IP67 |

| Ambient tem- perature | -15 to +60°C |

| Ambient humidity | 95%RH or less |

| Power supply and power consumption | 20 to 27.5 V DC, 2.5 W or less |

| Mass | FSZ08: 400 g FSZ15: 500 g FSZ25: 600 g |

| Temperature measurement (Optional) | Pipe surface temperature measurement |