Oil Immersed Transformers

Fuji Electric has a long-standing reputation for delivering high-performance oil-immersed transformers to customers worldwide. Our product lineup includes Generator Step-Up Transformers (GSU), Power Transformers (PTR), and Distribution Transformers (DTR). Engineered for efficiency, durability, and reliability, Fuji Electric transformers are trusted by leading industries across the globe.

Sales Information:

Transformer Lineup

Fuji Electric offers a full range of oil-immersed transformer solutions to meet diverse application needs. From large-scale power generation and transmission to localized distribution, each transformer is engineered for optimal performance, safety, and long-term reliability. Explore our product categories below to find the best fit for your operation.

Key Features

Well-arranged core construction

The core is made of top-class Hi-B (high magnetic flux density) oriented silicon steel plate with improved exciting characteristics such as core loss, exciting current, magnetostriction, etc. The core is tightened uniformly with tempered plastic bands and also a core election equipment is employed, thus making it small-sized and lightweight together with low noise level.

-

Since there are no holes in the core plate, it provides for easy machining and improve the characteristics.

-

The core tightening bolts are cooled directly by insulation oil since they pass through the oil duct.

-

Because of using the tempered plastic bands, the core plate ends can be tightened securely.

-

As a result of improving the space factor of the core, the transformer can be made compact and lightweight.

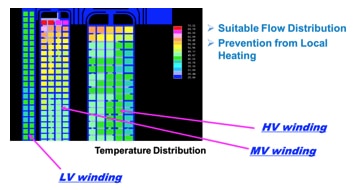

Winding construction

Various windings have been developed in addition to the conventional twin-coil disc winding, and according to the purpose of use, the optimum winding is selected from those listed below, allowing the specific characteristics to be fully utilized.

- For low voltage and large current:

- Cylindrical layer winding (using transposed conductor)

- Helical winding

- For high voltage and surge protection:

- High series capacitance disc winding

- For wide-range tap:

- Multi-parallel cylindrical tap winding

For the windings of extra high voltage transformers, a high series capacitance disc winding, in which potential oscillation in the winding is suppressed to a minimum when impulse voltage is applied. The insulation in the windings, across windings and across winding and ground has been made very reliable as a result of numerous fundamental experiments and improvement of potential distribution and insulation strength by utilizing a computer. Also, extra high voltage are given a partial discharge test to verify the insulation reliability before leaving the plant.

As the winding conductor, a transposed conductor has been employed besides the rectangular copper wire to cope with the increase in transformer capacity.

The transposed conductor is made as follows;

With the finely divided rectangular conductors each insulated with synthetic resin consisting mainly of polyvinyl formal, the odd-numbered conductors are arranged in two rows as shown in Fig.2, the mutual positions of conductors are transposed in turn at a certain pitch, and with these conductors put together as a unit, the same electric insulation Kraft paper as used for ordinary rectangular copper wires is wound thereon for insulation. When this transposed conductor is used, the following merits are available:

-

Reduction in stray load loss in winding

-

Prevention of local overheat in winding

-

Improvement in characteristics, and

-

Accomplishment of lightweight and compact transformers

-

Decrease in the number of connecting parts in winding

The optimum cooling system will be selected out of following according to the customer ‘s requirements and also taking into account the transformer capacity and circumstances at the installation site.

1) ONAN, 2) ONAF, 3) ODAN, 4)ODAF, 5) OFOW

In a large core, the core internal temperature rise is kept under the limit by providing a cooling oil duct at right angles to the steel plate stacking direction. For the winding, an oil duct is installed in the coil as required for obtaining a high cooling effect.

Applications of Oil-Immersed Transformers

Fuji Electric oil-immersed transformers are used across a wide range of industries and energy systems. Their robust design and reliable performance make them ideal for:

- Power generation plants – Generator step-up transformers for efficient energy transmission

- Transmission & distribution networks – Large-scale power delivery with reduced losses

- Industrial facilities – Stable power supply for manufacturing and heavy equipment

- Commercial & residential areas – Safe and dependable local energy distribution

By adapting to diverse operating conditions, our transformers ensure consistent, long-term performance wherever reliable energy is required.

Why Choose Fuji Electric?

With decades of global experience, Fuji Electric has become a trusted partner in delivering energy solutions that prioritize performance and reliability. Our oil-immersed transformers are:

- Built to international standards for safety, efficiency, and compliance

- Engineered for efficiency with advanced designs that reduce losses and operating costs

- Tested for durability to ensure stable operation in even the most demanding environments

- Backed by expert support with responsive sales and service teams worldwide

Choosing Fuji Electric means investing in transformers that keep power systems running smoothly, efficiently, and reliably.