There are several key characteristics that should be considered to ensure it provides effective and reliable protection in a specific application.

Here are the primary aspects to look at:

- Current Rating: Choose a thermal overload relay that matches the full-load current of the motor or circuit it is protecting. The relay should be capable of handling the normal operating current without tripping.

- Adjustable Trip Settings: Many thermal overload relays offer adjustable trip settings. This allows you to set the trip current to match the motor’s specific characteristics and the conditions of the application.

- Trip Class: The trip class of a thermal overload relay indicates the time it takes for the relay to trip at 600% of its rated current. Common trip classes include 10, 20, and 30, with lower numbers indicating faster tripping. The choice depends on the type of motor and its start-up and running characteristics.

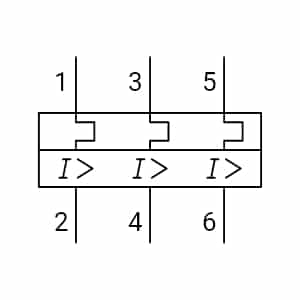

- Phase Loss Sensitivity: Good thermal overload relays can detect a phase loss (single phasing) condition, which is a common cause of motor overheating and damage.

- Temperature Compensation: The relay should be able to compensate for ambient temperature variations to avoid nuisance tripping or failure to trip when necessary.

- Reset Mechanism: Thermal overload relays can have either manual or automatic resets. The choice depends on the application and the desired level of intervention in case of a trip.

- Integration with Contactors: Many thermal overload relays are designed to be integrated with specific contactors. Ensure compatibility between the relay and the contactor it will be used with.

- Size and Mounting: Consider the physical dimensions of the relay and how it will be mounted in your system. It should fit within your existing setup or control panel.

- Environmental Conditions: Evaluate the operating environment, including temperature, humidity, and exposure to contaminants, which can affect the relay’s performance.

- Durability and Reliability: Choose a relay from a reputable manufacturer known for quality products. The relay should be robust and reliable, especially for critical applications.

- Certifications and Standards: Ensure the relay meets relevant industry standards and certifications, especially those required for safety and compliance in your region or industry.

- Ease of Installation and Maintenance: Look for relays that are easy to install and maintain, particularly if frequent servicing or adjustments are anticipated.

Select a thermal overload relay with these characteristics to provide effective protection for your motors and electrical equipment against the potential dangers of overloads.