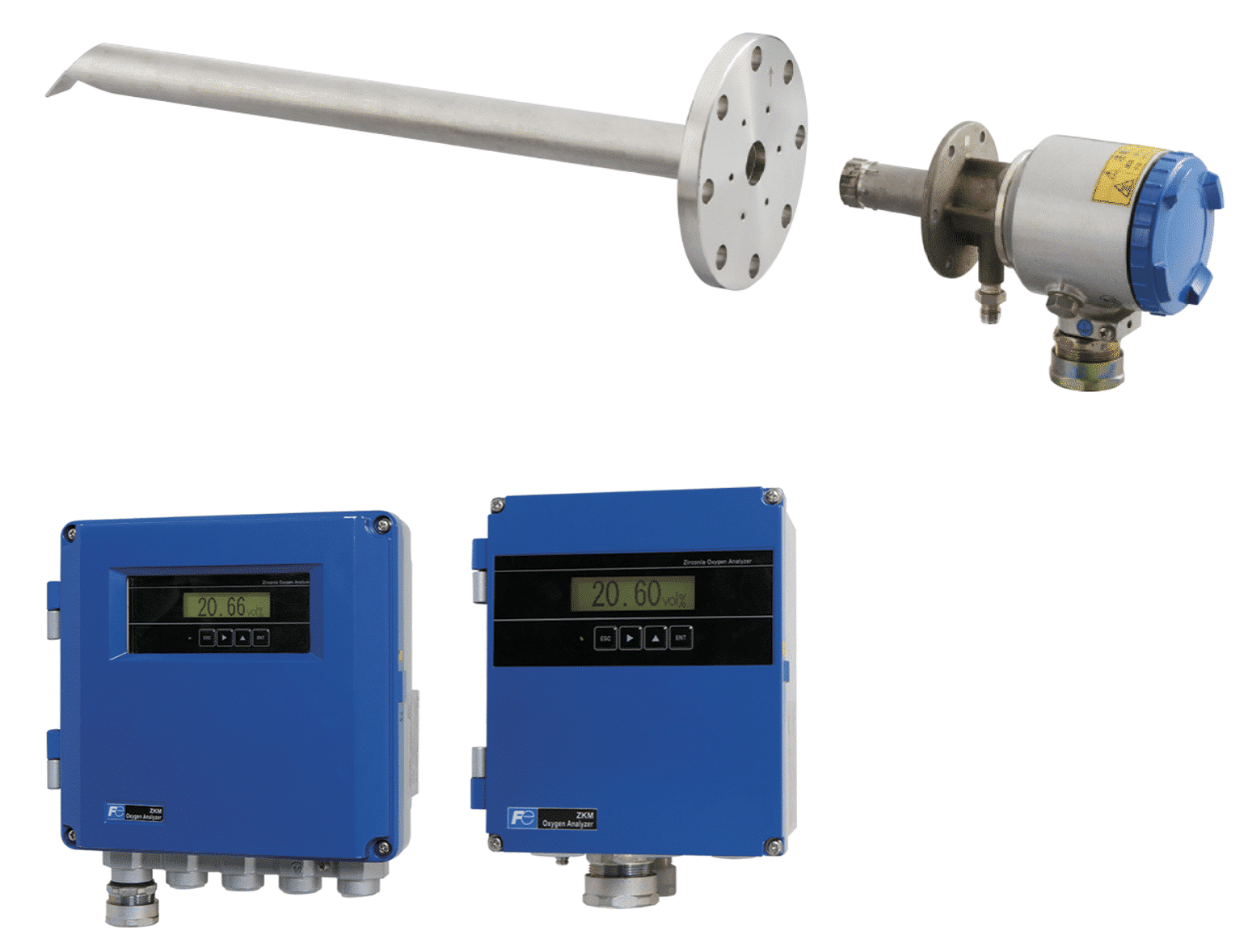

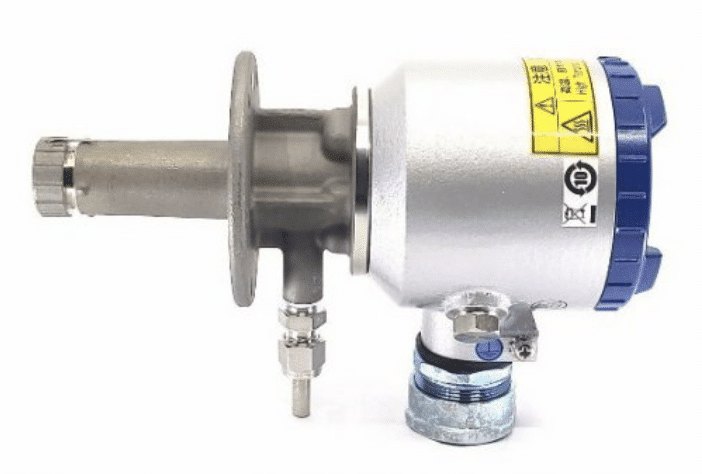

ATEX In-Situ Zirconia Oxygen Analyzers

Optimization of combustion efficiency and compliance with environmental standards. Ideal for combustion control in boilers, incinerators, and furnaces. Lowering CO₂, SOx, and NOx emissions while saving energy. This oxygen analyzer is used to continuously measure oxygen concentration in the combustion exhaust gas of industrial boilers or furnaces. This is ideally suited for combustion management and control, such as garbage incinerators and smallest to largest sized boilers. Our products are combustion controllers which achieve significant energy-saving effect.

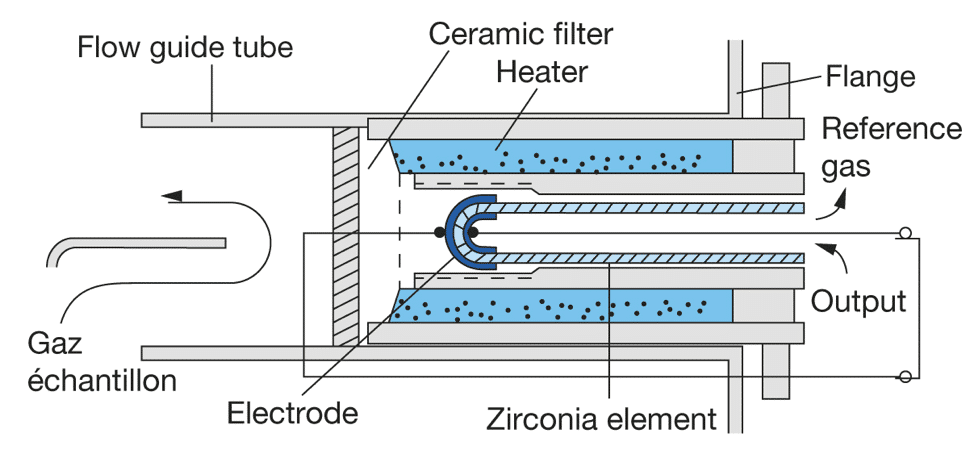

Principle

The analyzer makes use of the property of zirconium oxide that conducts oxygen ion when heated.

The analyzer can obtain O₂ concentration by sensing the electromotive force generated by the difference of O₂ concentration between air and the sample gas.

Applications

- Steel

- Energy

- Petroleum

- Petrochemicals

- Ceramics

- Paper and pulp

- Food

- Textile industries

Combustion process

- Garbage incinerators

- Smallest to largest boilers

- Combustion controllers

Advantages

- New Hart Protocole

- Reduction of excess combustion air

- Economy by increasing combustion efficiency

- Longevity of the combustion plant

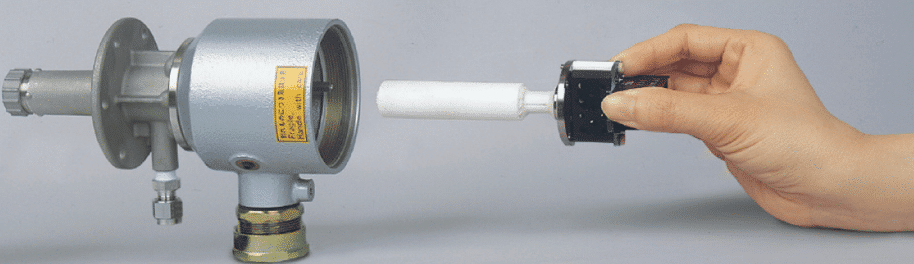

- Easily replaceable zirconia element

- High safety level

-

- The converter cuts off the power supply for the detector when detecting a burnout of thermocouple.

- The converter also cuts off the power supply at emergency, in response to an external contact input.

- The key lock function prevents operational errors.

Features

- Longest lifetime sensor

- Easily replaceable zirconia element reducing maintenance cost

- User friendly

- No instrument air required

- No Flue gas extraction required

- Fast response (4–7 seconds)

- Predictive and advanced diagnostics

- IP66 or IP67 enclosure

- RS-485 or HART™ communication

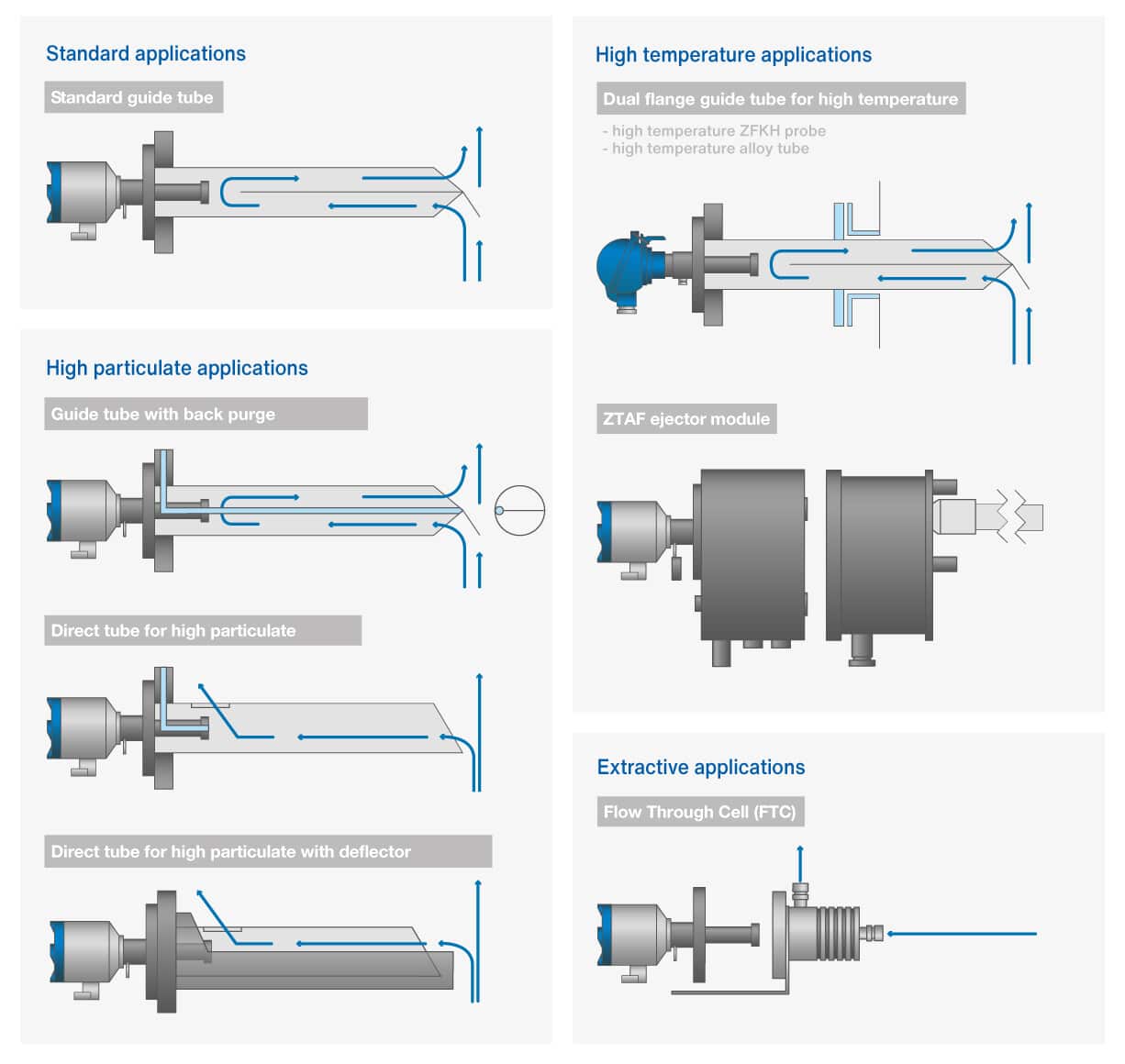

Depending on the conditions of yout processes you can combine the modules below