Pressure Transmitters

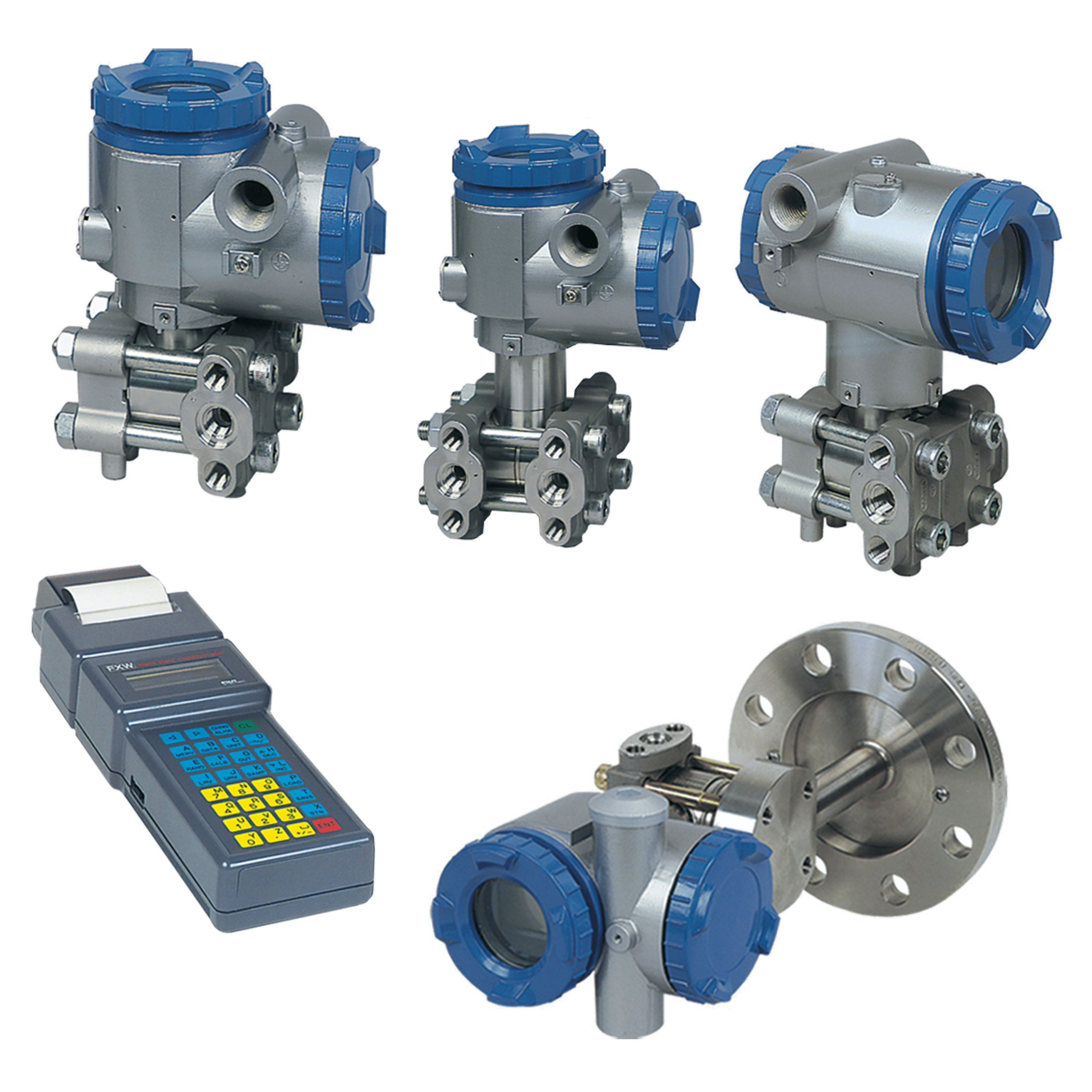

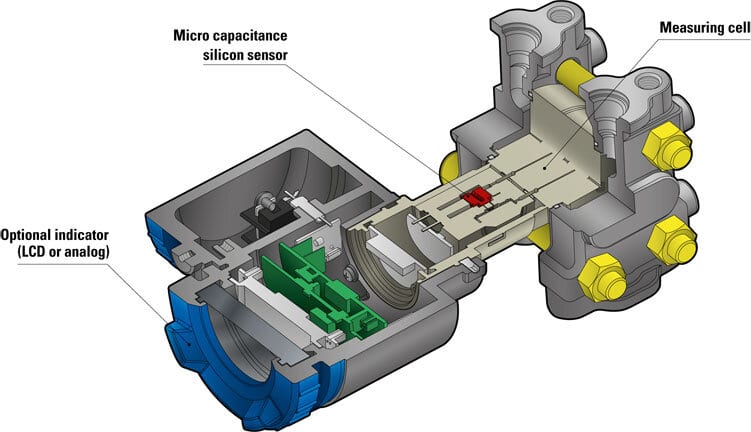

Fuji Electric offers high performance Pressure Transmitters and has a long heritage of reliable performance with over 1,000,000 FCX series electronic transmitters sold worldwide. The micro-capacitance silicon sensor that is produced with our micro-machining technology is the key component of FCX transmitters’ high performance and reliability. A wide range of models are available for gauge or differential pressure, and flow with competitive low cost options.

Excellent repeatability – Easy maintenance – High accuracy

- Available in a “Smart” version (4-20 mA + superimposed digital signal) with the Fuji proprietary protocol and the Hart® protocol

- Equipped with the Fieldbus Foundation H1 protocol (option)

- Manufactured according to ISO9001 standards

FCX-AII VG : Integrated Safety Systems (IEC 61508)

- With a SIL 3 capability, the FCX-AII in its VG version is SIL2 (HFT=0) or SIL 3 (HFT=1) certified

- Its 97% safety failure ratio allows it to offer the best SFF available on the pressure transmitter market

- The FCX-AII VG has a sampling time of 40 ms and a response time of 80 ms, making it one of the fastest pressure transmitters on the market

Specifications

- Accuracy :

- ± 0.065% of the calibrated span (standard)

- ± 0.04% of the calibrated span (option)

- Long term stability : ± 0.1% max.span /10 years

- Differential pressure transmitters for static pressure : up to 1035 bar (15 000 PSI)

- Various materials available for wetted parts : Tantalum, Monel, Hastelloy C, ou PVDF

- Applications : chemicals, petrochemicals, energy, steel-making, paper, food & beverage or water treatment

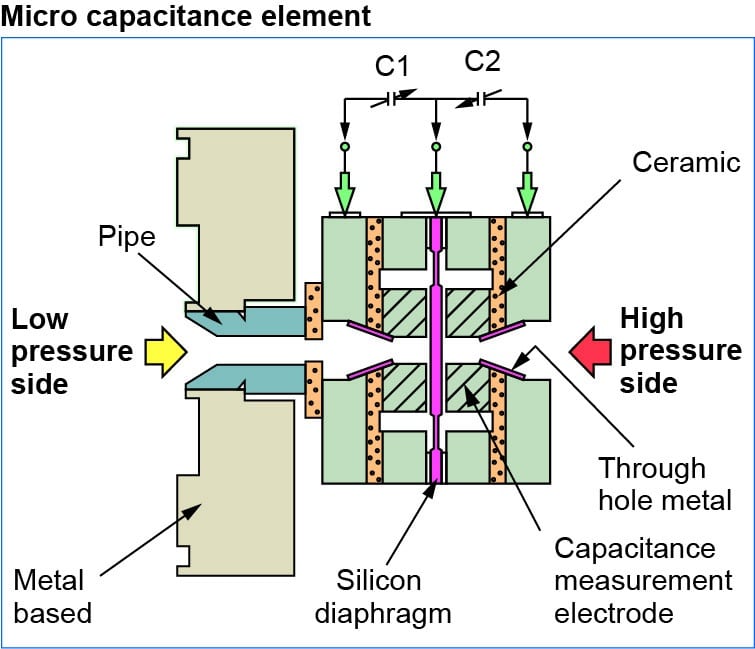

Cells sensitive element : Silicon chip Micro capacitance based technology

|

Advantages :

|

Measurement principle : The sensitive element receives the differential pressure, which causes the two capacity values to vary. It is mounted “floating” in the neck of the measurement cell to improve the static pressure and temperature characteristics. |

Optional functionality: Digital indicator – burnout current – maintenance – communication

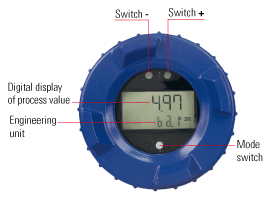

DIGITAL INDICATOR

The FCX-All V5 transmitter may be equipped with an analog or digital indicator. The digital indicator is based on LCD technology and shows the information on 2 lines each of 6 digits and also includes 3 push buttons. The indicator enables the measurement in physical units and the local configuration of the transmitter.

Main settings

- Zero/Span calibration without reference pressure service

- Linear or square root signal

- Damping

- Digital indicator configuration

- Zero/Span calibration

- Self-diagnosis

- Output circuit calibration

- Direction and value of burnout

Burnout current

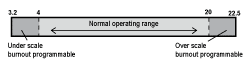

In conformance with the recommendations of NAMUR NE 43, the output of the transmitter can be driven to a specific value should the transmitter experience an internal failure. The standard output signal limits are 3.2 to 22.5 mA. In case of a transmitter failure, the burnout direction can be down scaled (3.2 to 4 mA) or up scaled (20 to 22.5 mA), being programmable.

Maintenance functions

The calibration parameters are saved in the transmitter. At any time it is possible to come back to the factory calibration of the transmitter. Min and max temperatures are stored in the transmitter memory. It is always possible to visualize the values in a specific menu on the screen of the hand held communicator. All the adjustment functions of the transmitter can be locked by a password (the external adjusting screw is also locked).

Communication

HAND HELD COMMUNICATORS

The FCX-All V5 is a «smart» pressure transmitter that provides a 4-20 mA output with the HART® digital communication protocol. The FCX-All V5 is also available with the Foundation™ Fieldbus H1 communication protocol. In its smart version, FCX-All V5 pressure transmitters can be configured using any hand held terminal that accepts HART® device description (DD) files.

FIELD DEVICE TOOL/DEVICE TYPE MANAGER ENVIRONMENTS

Fuji Electric provides a full DTM package that allows FDT users to accede and configure all parameters of the FCX-All pressure transmitters. The Fuji Electric DTM package is compatible with all FCX smart series pressure transmitters.

Transmitter measurement diaphragm materials

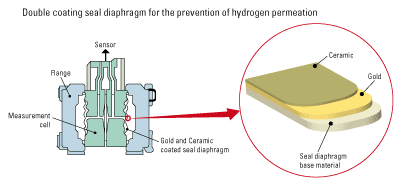

COATING FOR PREVENTION OF HYDROGEN DIFFUSION IN THE MEASUREMENT CELL (HYDROGEN SULPHIDE) : GOLD AND CERAMIC

For certain configurations, the process fluids generate hydrogen atoms that may be diffused through the metal diaphragm. The contamination of the oil associated with this diffusion degrades the transmitter’s measurement accuracy and life time. Thanks to our gold and ceramic double-coating diaphragm, the hydrogen’s permeation is stopped.

In this configuration, the transmitters may be used in sulphur reduction installations, hydrogen production units, oil refineries and putrefaction mud treatment works.

ANTI CORROSIVE AND CHEMICAL ATTACKS : HASTELLOY C, TANTALUM, MONEL

Different materials and coatings are available for the pressure transmitter diaphragms to guarantee the longevity and reliability of your measurements.

| Gold & ceramic coating | Sulphur reduction installations, hydrogen production units, oil refineries and putrefaction mud treatment works, ionised gas (hydrogen sulphide) |

|---|---|

| Tantalum | Hydrochloric acid, sulphuric acid, nitric acid, aqua regia |

| Titanium | Sodium chloride, sulphate compound |

| Hastelloy-C | Organic acid, inorganic acid, alkaline type |

| Monel | Alkaline type, fluorinated acid |

| Zirconium | Hydrochloric acid, caustic soda, whitening agent |