Single-Beam NDIR Gas Analyzer (ZRE)

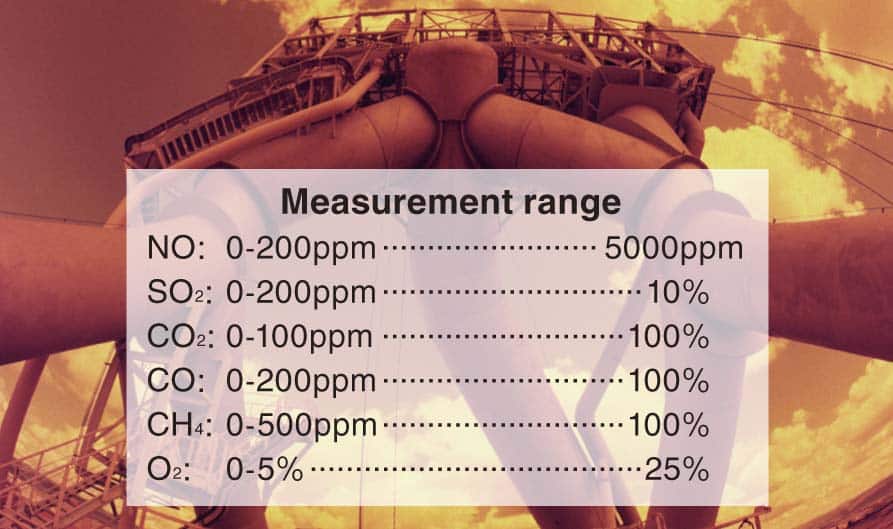

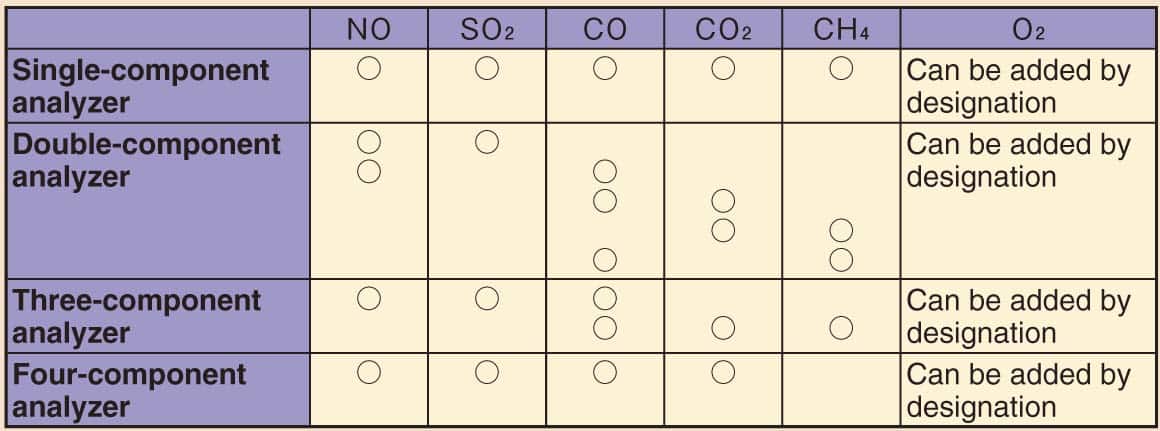

Simultaneous and continuous measurement of up to 5 components among NO, SO2, CO, CO2, CH4, and O2in incinerators or boilers

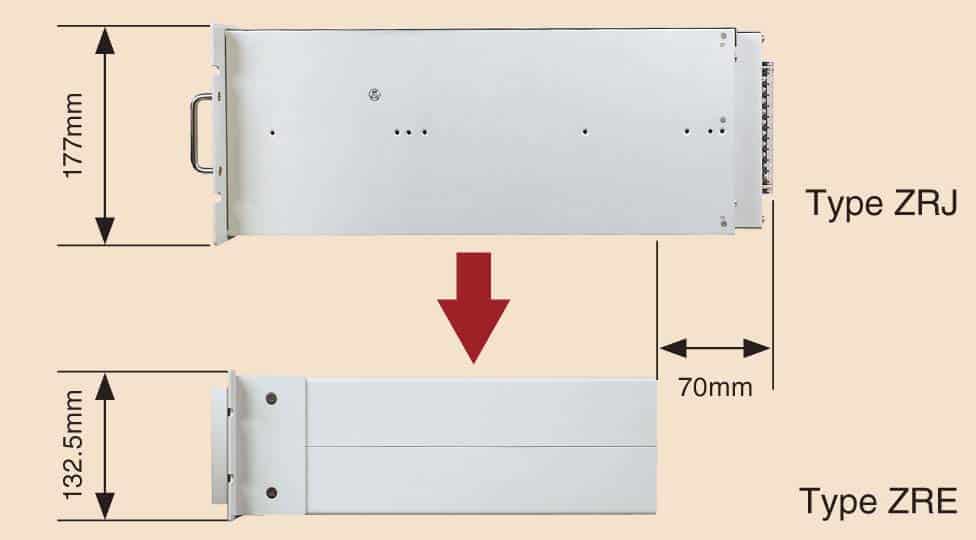

- Compact design

- Long-term superior stability

- Easy-to-see LCD

- Optional functions include: auto calibration, concentration alarm, remote range-switching, and more.

- Hardly affected by moisture interference

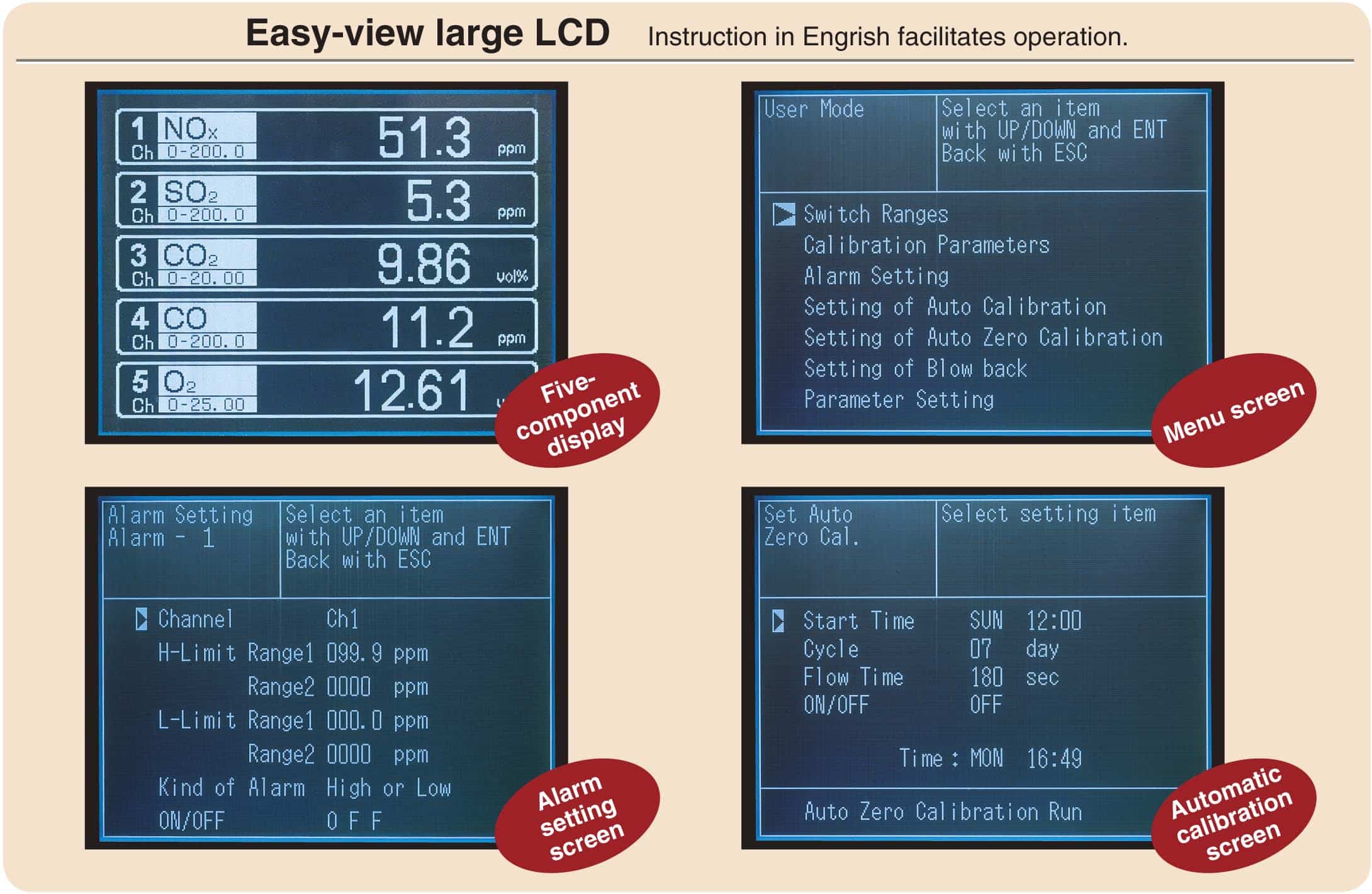

Easy-to-see LCD

Compact and lightweight (approx. 8 kg)

Continuous measurement of up to 5 components

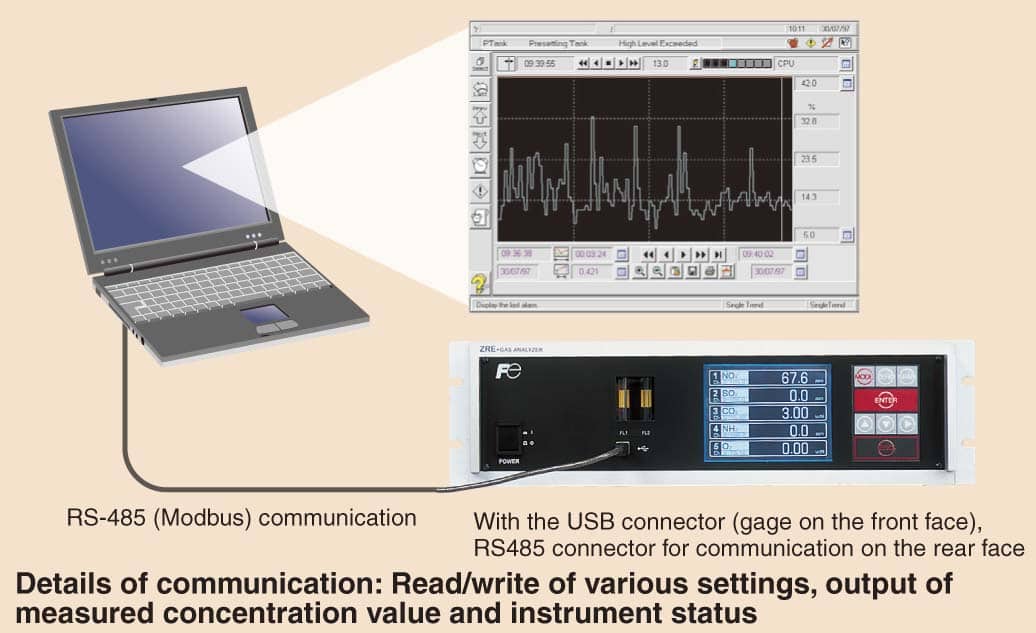

RS-485 (MODBUS) communication

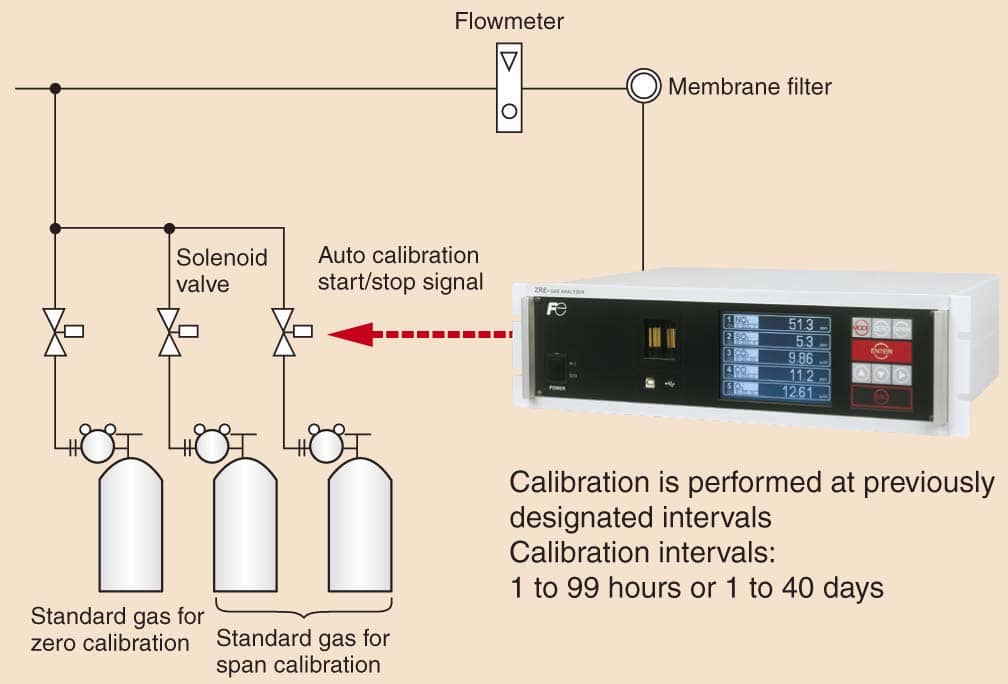

Automatic calibration eliminates the need for troublesome calibration work

Specifications

| Principle | NO, SO2, CO, CO2, CH4: Non dispersive infrared sensor (single beam system) O2: built-in magnetic or galvanic sensor, or external zirconia sensor (ZFK7) |

|---|---|

| Ranges | NO: 0–200 ppm…5000 ppm SO2: 0–200 ppm…0–10 vol% CO2: 0–100 ppm…0–100 vol% CO: 0–200 ppm…0–100 vol% CH4: 0–500 ppm…0–100 vol% O2: 0–5 vol%…25 vol% Up to 2 ranges per component, switchable. Maximum range ratio 1 : 10 (excluding O2) |

| Repeatability | ±0.5% FS |

| Linearity | ±1.0% FS |

| Zero drift | ≤ ±2% FS per week |

| Span drift | ≤ ±2% FS per week |

| Response time | ≤ 60 s (90% response from gas inlet) Time depends on the number of components and range |

| Analog output | 4–20 mA DC or 0–1 V DC (max. 12 points) Instantaneous values of each component |

| Option | O2-corrected instantaneous value, O2 corrected average value, O2 average |

| Display | Backlit LCD (Japanese, English, or Chinese) with automatic light off function Instantaneous value, O2-corrected instantaneous value, O2corrected average value, O2 average, parameter setpoints |

| Range switching | by key operation, automatic, or by external contact input (option) |

| Contact input (option) | Voltage contact input (12–24 V DC, 15 mA max.) up to 9 points Range switch, auto-calibration start, output signal hold, average reset |

| Contact output (option) | SPDT relay contact (up to 15 points) Range identification, device error, calibration error, auto-calibration status, high/low limit alarm, pump ON/OFF, solenoid valve drive output for auto calibration |

| Communication (option) | RS-485 (MODBUS), USB type-B connector Reading/writing parameter values, measured values, device status |

| Flowmeter | Included |

| Gas inlet/outlet | Rc1/4 or NPT 1/4 |

| Structure | Steel casing, for indoor use |

| Operating environment | -5°C to 45°C, RH 95% or lower (no condensation) |

| Mounting | 19-inch rack mount, panel mount, or desktop |

| Power supply voltage | 100–240 V AC, 50/60 Hz, 100 VA |

| Dimensions (H x W x D) in mm | 133 x 483 x 418 (19-inch rack mount) 133 x 440 x 418 (panel mount) 149 x 440 x 418 (desktop) |

| Weight | Approx. 8 kg (5-component analyzer) |

| Certification | CE marking |

Sample gas conditions

| Flow rate | 0.5 L/min ±0.2 L/min |

|---|---|

| Temperature | 0–50°C |

| Pressure | ≤ 10 kPa |

| Dust | ≤ 100 μg/Nm3 with particle size ≤ 0.3 μm |

| Mist | Unallowable |

| Moisture | Below the saturation vapor density at room temperature (non condensing) Below the saturation vapor density at 2°C (non condensing) for NO, SO2, and CO of the range below 200 ppm |

| Corrosive gas | HCl ≤ 1 ppm |