Thermal Conductivity Gas Analyzer (ZAF)

H2 continuous measurement with high accuracy with high accuracy

Measurable gas components H2、Ar、He、CH4、CO2

- Continuous measurement and real-time monitoring

- Operation by anyone using the display guide

- Lightweight and compact design to install anywhere

Applications

- Research facilities using hydrogen gas

- Monitoring of reductive atmosphere in industrial furnaces

- Semiconductor equipment (H2)

- Hydrogen generators (H2)

- Firing furnaces (H2)

- Gas generating plant (Ar, He, CH4)

- Superconducting equipment (He)

- Air separation plants (Ar)

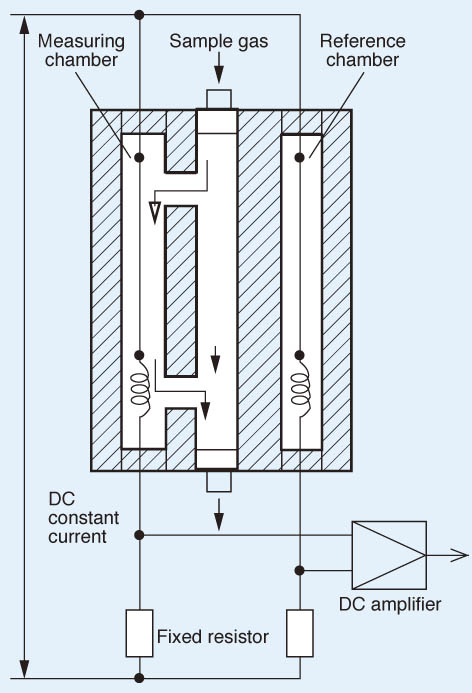

Principle

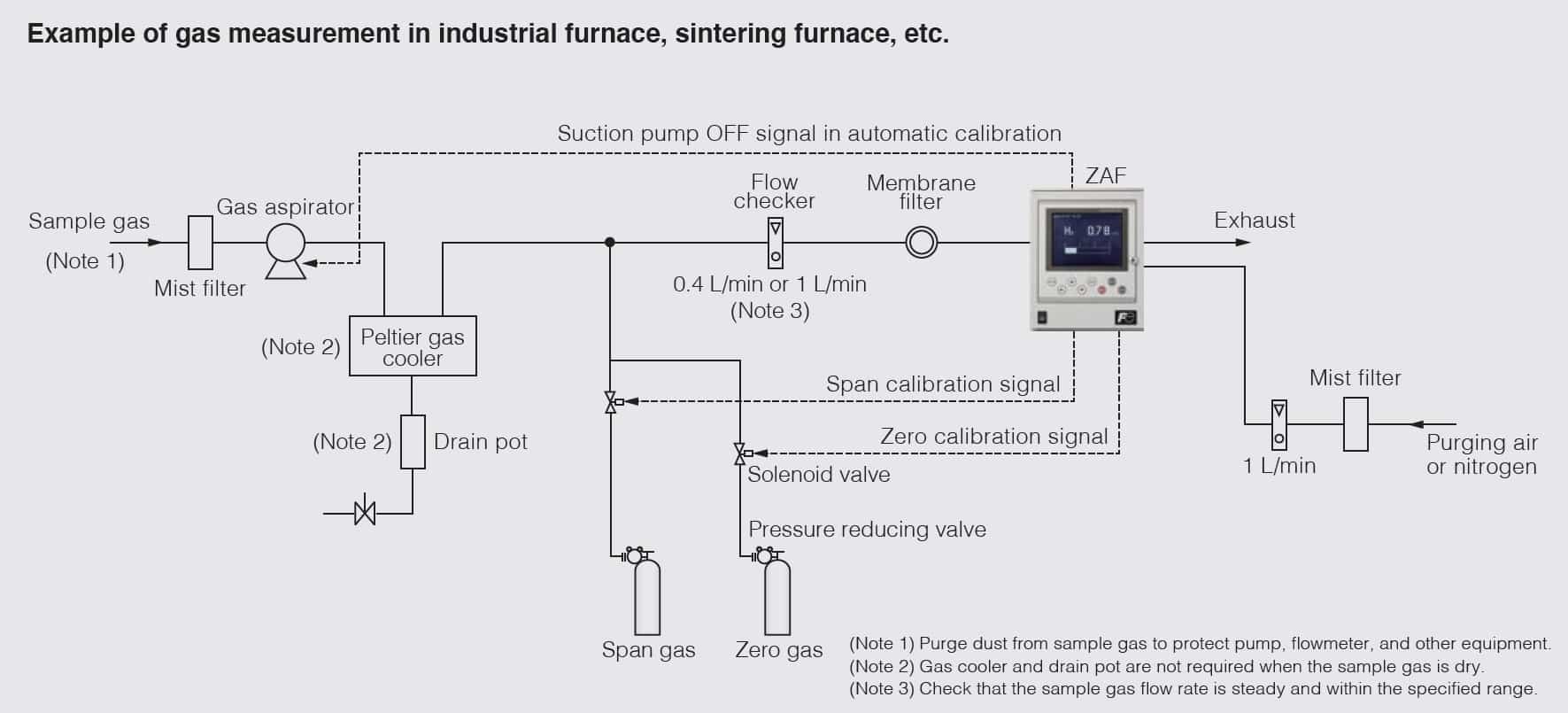

Gas sampling system diagram

Specifications

| Principle | Thermal conductivity |

|---|---|

| Components | He, Ar, H2, CH4, CO2 |

| Range | H2: 0–3 ‥‥ 100%, 100–90%, 100–80% He: 0–5 ‥‥ 100%, 100–90%, 100–80% Ar: 0–10 ‥‥ 100%, 100–90%, 100–80% CH4: 0–20 ‥‥ 100%, 100–80% |

| Display | LCD with back light |

| Display | 4-digit |

| Power supply & consumption | 100–240 V AC, 50/60 Hz, approx. 50 VA |

| Mounting | Panel mount |

| Dimensions (H x W x D) in mm | 240 × 192 × 213 |

| Weight | Approx. 5kg |

| Repeatability | ±1%FS |

| Drift | Zero point: ≤ ±2% FS per week (H2measurement) Span point: ≤ ±2% FS per week (H2measurement) |

| Response speed (90% response) |

Standard: ≤ 60 s (at flow rate 0.4 L/min) High speed: ≤ 10 s (at flow rate 1 L/min) allowed only for H2 measurement (reference gas N2) |